SPRING ’24 UPDATE: Firstly I owe all the regulars here a huge apology for the inexcusable lack of updates over the winter. I have been extremely busy with real life since the end of last summer and unfortunately website updates have taken a backseat. I’ll get back on track this year – honestly!

Usually at the end of a year I tend to post an overview of the major achievements and landmark areas of progress. This is really all covered on the Archive News tab at the top of the page, but the stand out achievement for 2023 was the removal of both engine doors and the installation of the Adour rear ends.

I’ve been accumulating parts to this end for a few years with the intention to give the impression of installed engines and am pretty happy with the result.

Over the winter the cockpit has been double covered to keep out the damp. As and when the weather finally improves (and it stops raining) the outer winter tarpaulin will be removed and I’ll get back into the cockpit tasks.

Looking forwards into this year there are a number of tasks that I’d like to get ticked off the to-do list. Getting full ground power back on the aircraft remains a major aim but this still relies on getting the Ground Power Unit serviceable. Likewise with the hydraulics but there is still a fair amount to do to get the hydraulic system complete.

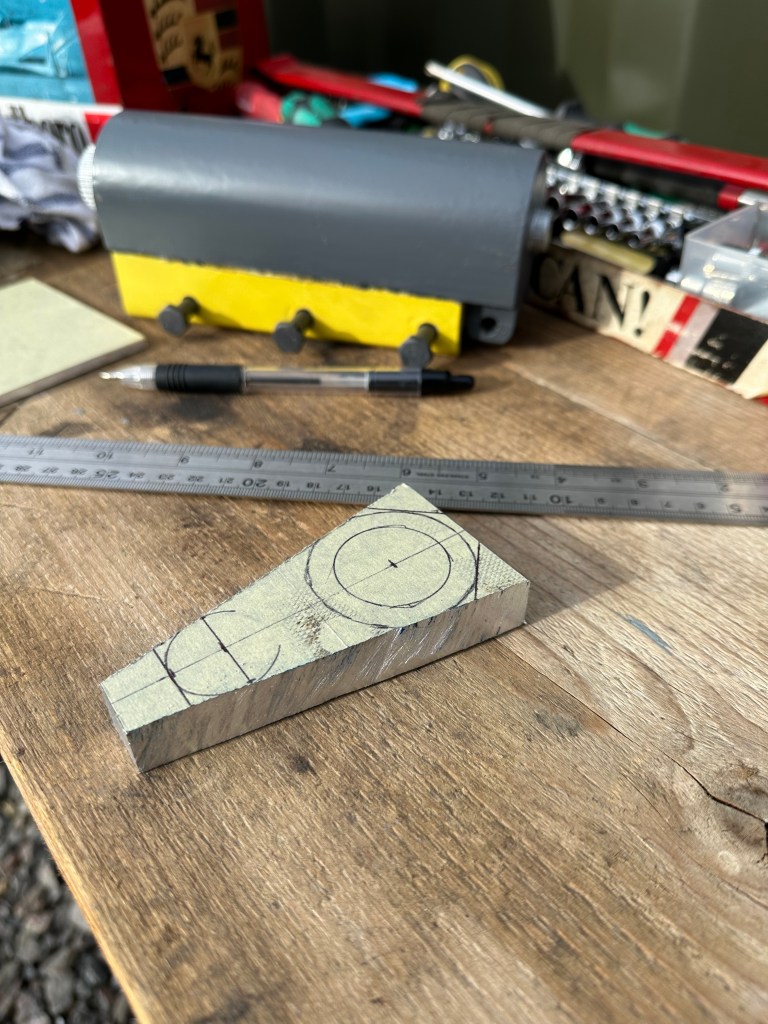

I also have a few ‘skunkworks’ projects underway some of which will be revealed as we get into the year.

Several people have asked if I’ll be holding an Open House Day this year. I’ve had a look at the calendar (which also has to align with my work schedule which tends to spill into weekends over the corse of the summer). Whilst it is difficult to find weekends that don’t clash with other aviation events, airshows/photoshoots etc, I have decided to plump for Saturday August the 17th.

And finally, a quick welcome to new followers of this page and the project.

Remember that previous monthly updates can be found on the ‘Archive News’ tab at the top of the page and that our range of merchandise can be found under the ‘Merchandise’ tab. Proceeds from all sales roll directly back into assisting the ongoing restoration.

As always, many thanks for the ongoing interest and support and apologies again for the downtime in news over the winter.

Neil

AUGUST ’23 UPDATE: This month has seen the completion of the ‘engine’ installation as well as a few other tasks as we make preparations for the Open House day on Sept 16th.

Early in August I had the coaming panel out again as I continued to try and troubleshoot the non-cancelling Master Caution. I’ve tried two 2W Control Units now and unless they both have the exact same snag (still a possibility) the problem lays elsewhere – or there is something latched in a condition that means the warning can’t be cancelled. I’ll get back to this at a later date.

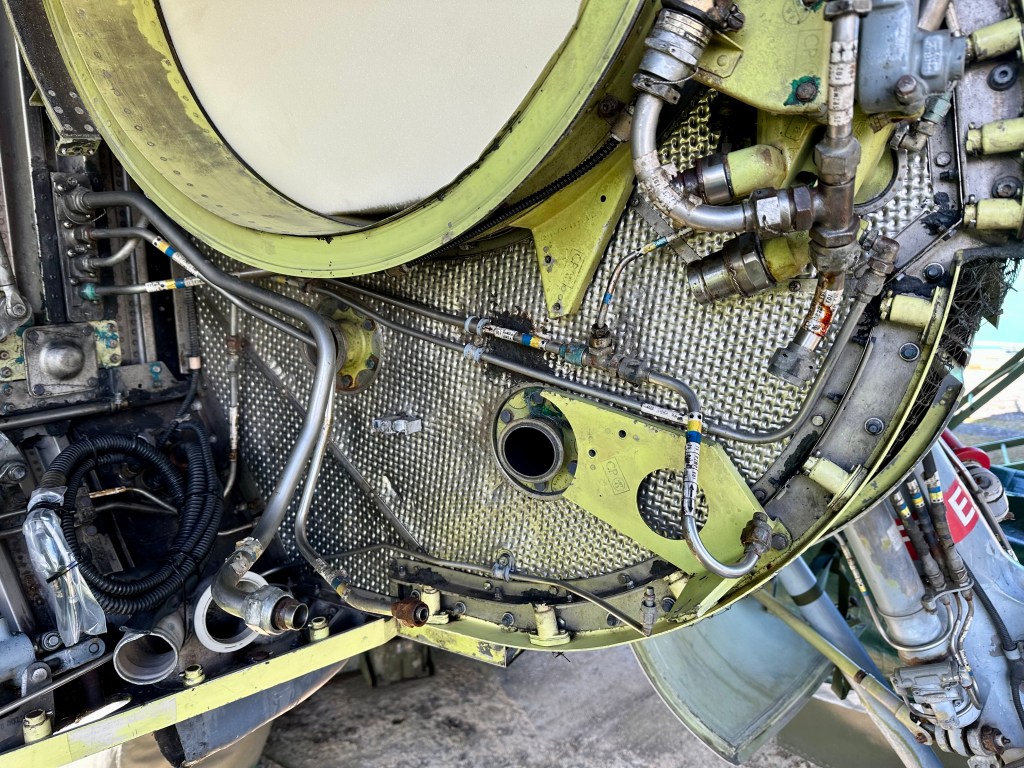

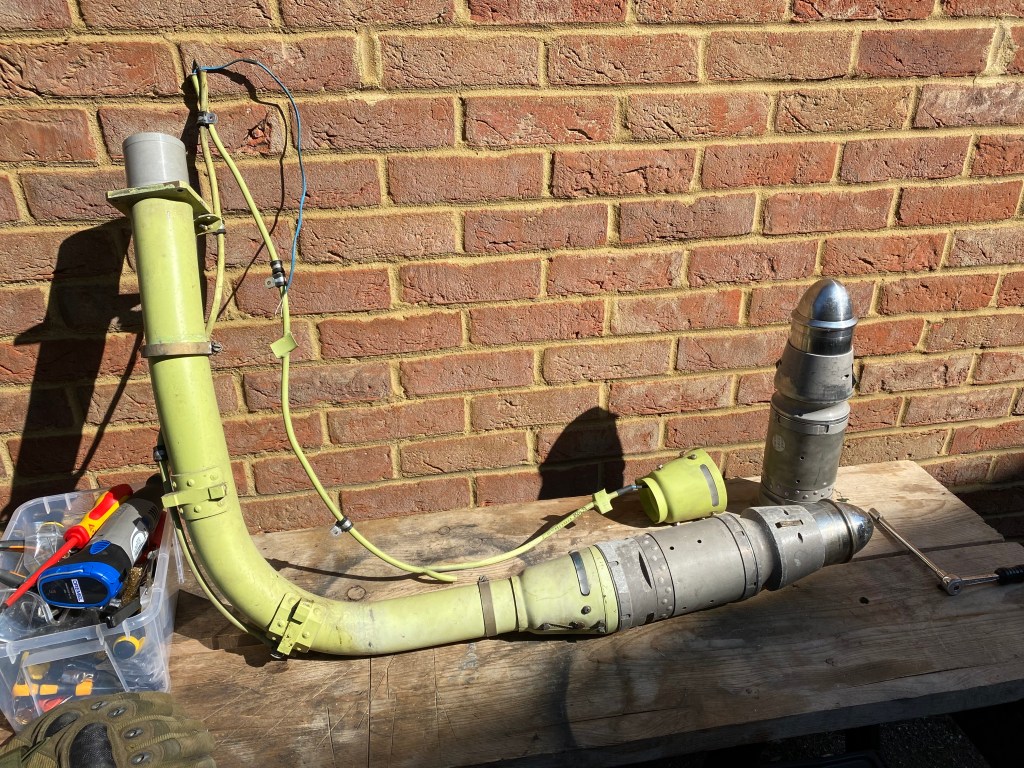

In Engine world the port afterburner module was hung in place. Based on the experience gained when we fitted the starboard installation so this was a relatively straightforwards procedure and we had all the parts in place to achieve the hang and door refit all in one day.

With the burner section secured in position the door was refitted and it was possible to finally view the complete rear ends. I’m pretty pleased with the way these have turned out.

Many people have asked ‘Why don’t you fit real engines?’ and there are a whole host of reasons why I haven’t, not least of which are budget and availability. Even if I did have budget and engines were available, I’d still need specialist equipment to hang full engines (that I don’t have), I wouldn’t be able to set them up or run them (I don’t have the experience, Enstone wouldn’t be the right location and it would need the restoration of a myriad of ancillary systems). Obviously if engines suddenly appeared I’d do what I could to make it happen – but it’s not a scenario I foresee.

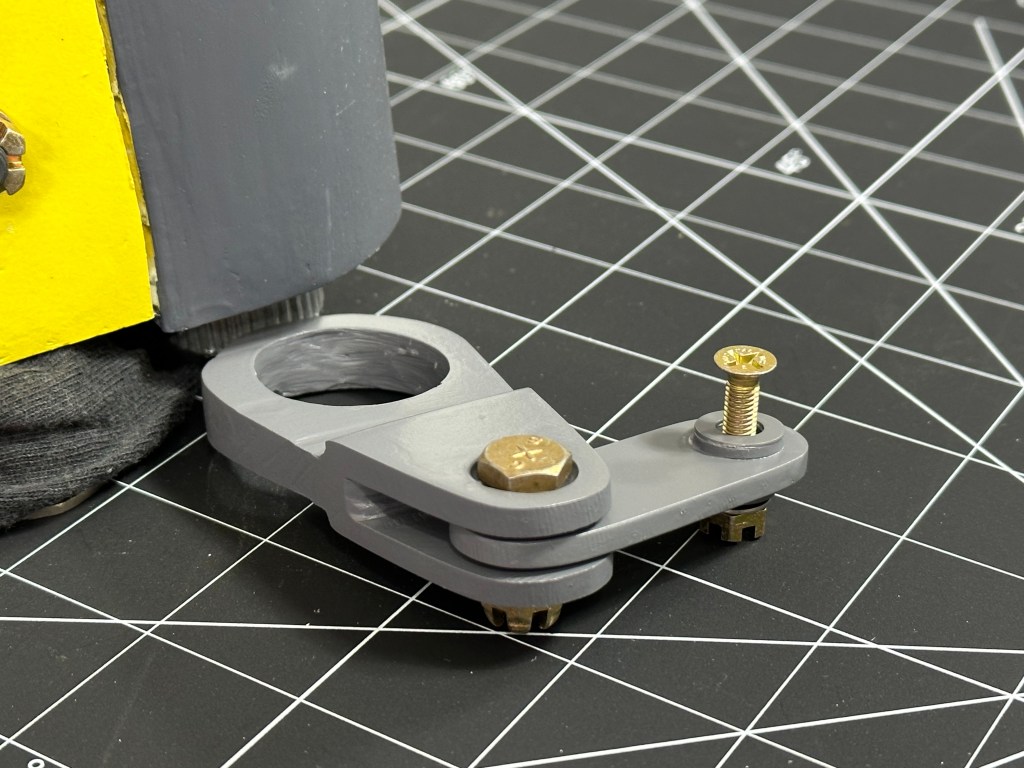

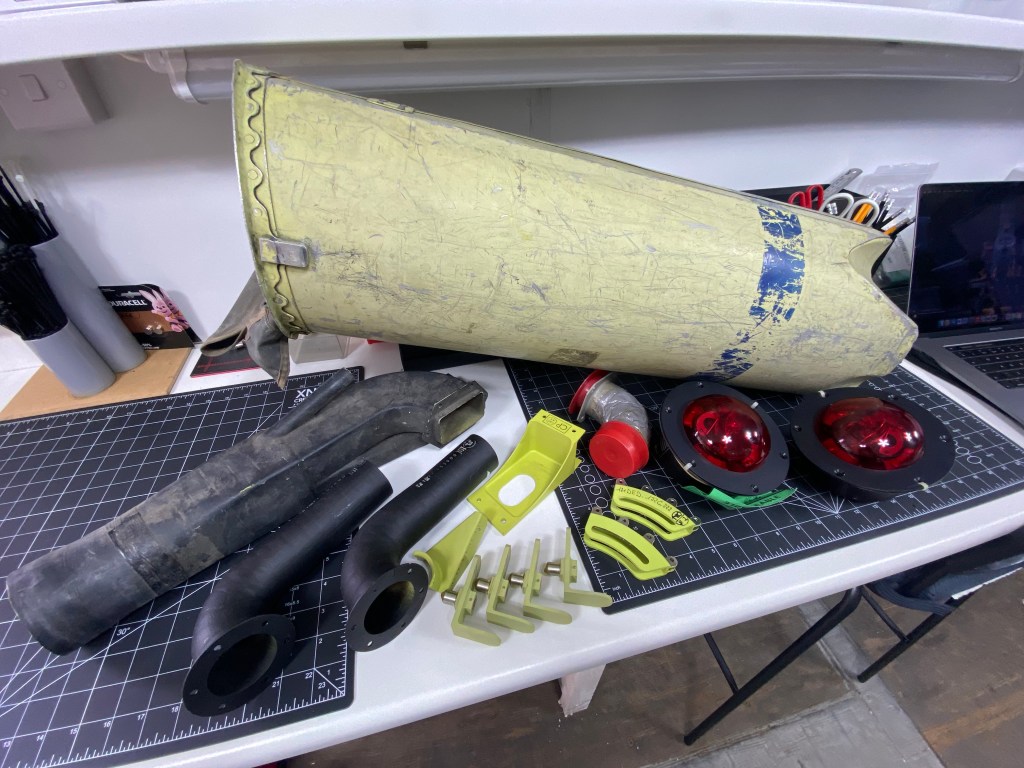

Following the completion of the engine sections attention turned to rebuilding the CBLS that I’d sourced earlier this year. It had been missing it’s ERU’s so after I managed to find a set of four I set about installing them.

With the aircraft being an OCU airframe the CBLS installation is a valid one and I will probably hang this on one of the outboard pylons.

And that just about wraps up progress on the aircraft for this month as we now look to prepare for the Open House Day on September the 16th. Many thanks to those that have already registered to attend. If anyone has any specific areas of interest to have a look at on the day please feel free to let me know.

As usual it would help us immensely for you to pre-register your interest in attending (there’s no charge for coming) as it will assist us with parking, catering etc.

To register for an e-ticket please visit this link: https://www.eventbrite.co.uk/e/xx764-2023-open-house-registration-640854612397?aff=oddtdtcreator

And finally, a quick welcome to new followers of this page and the project. Remember that previous monthly updates can be found on the ‘Archive News’ tab at the top of the page.

As always, many thanks for the ongoing interest and support.

Neil

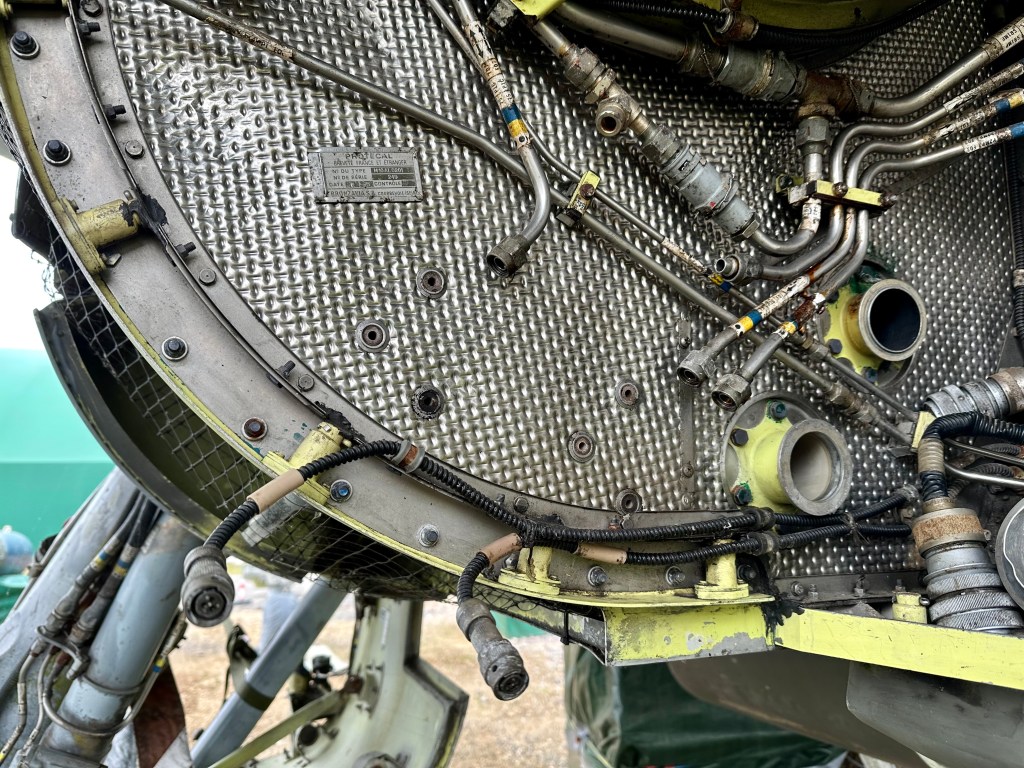

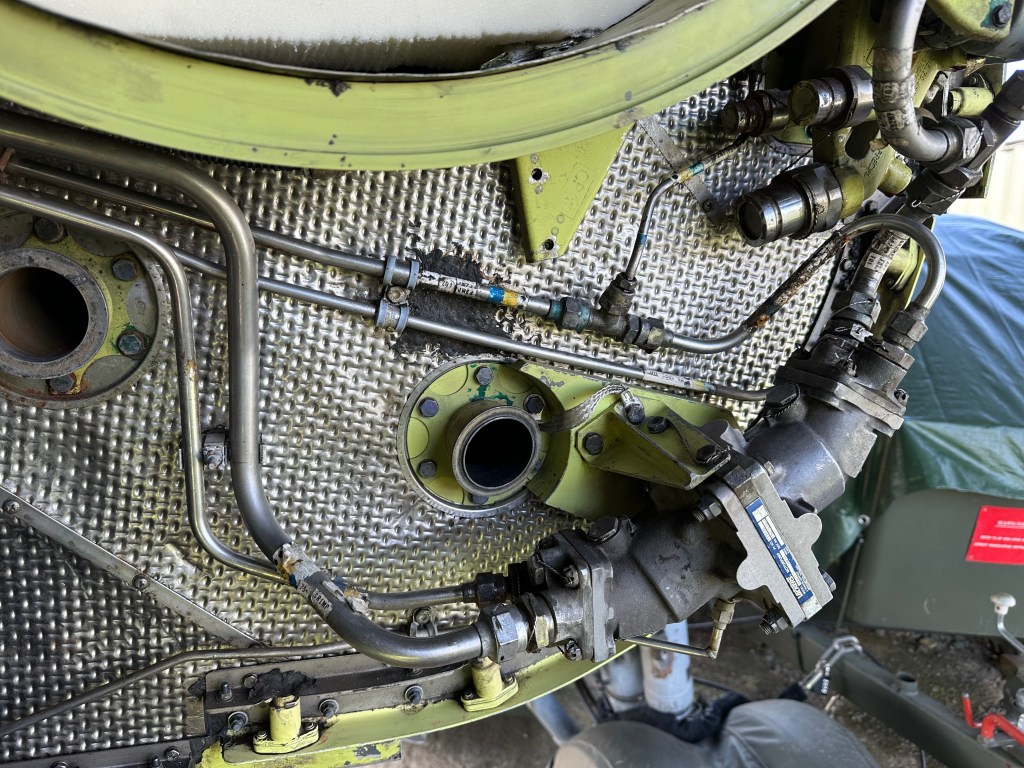

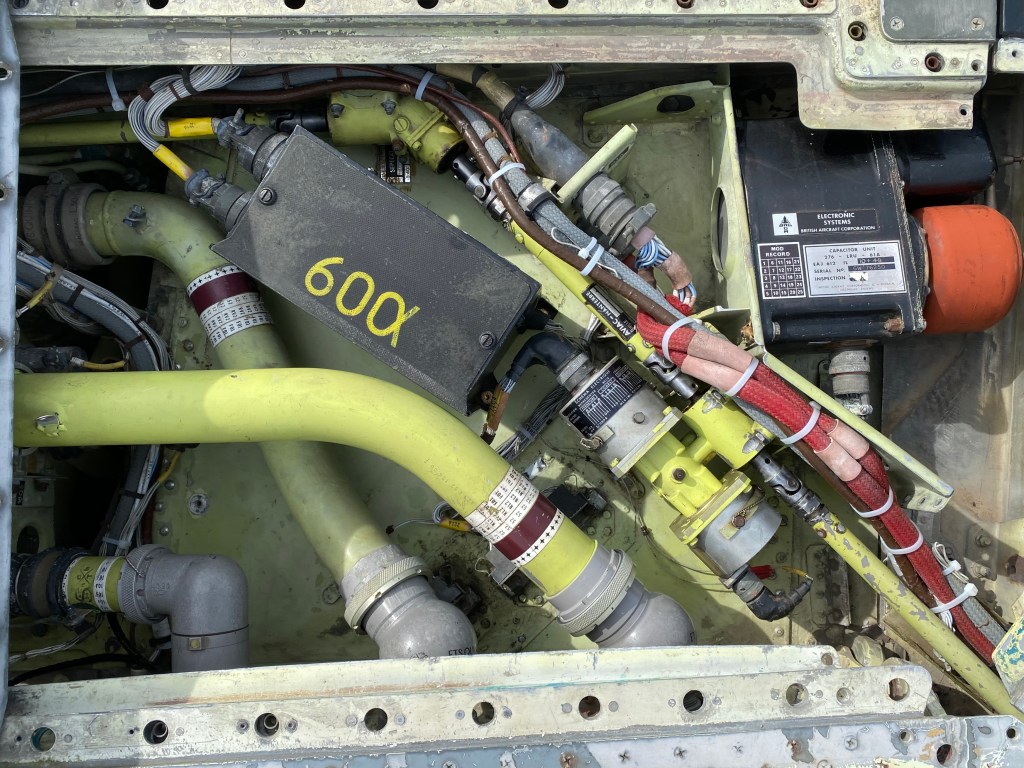

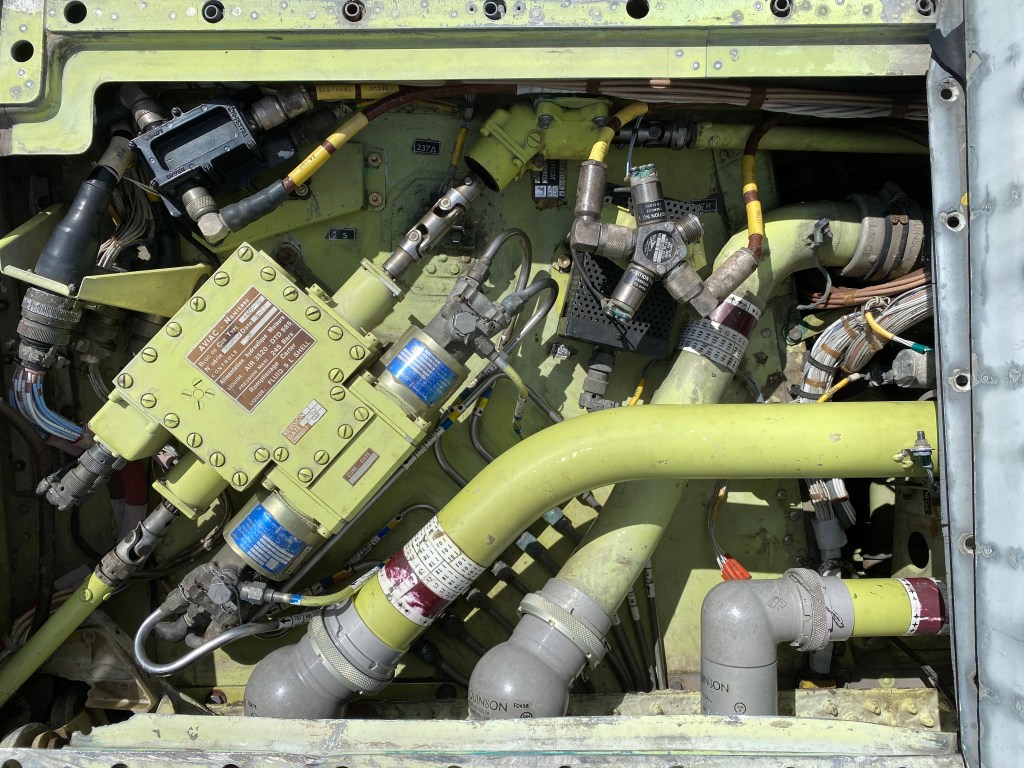

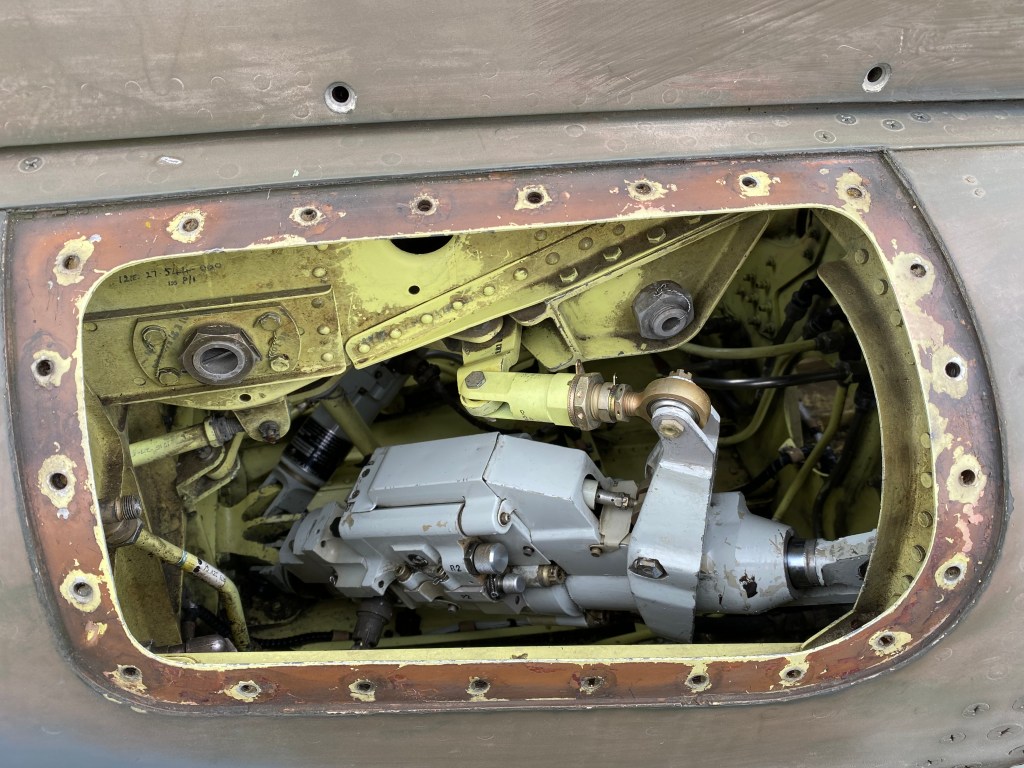

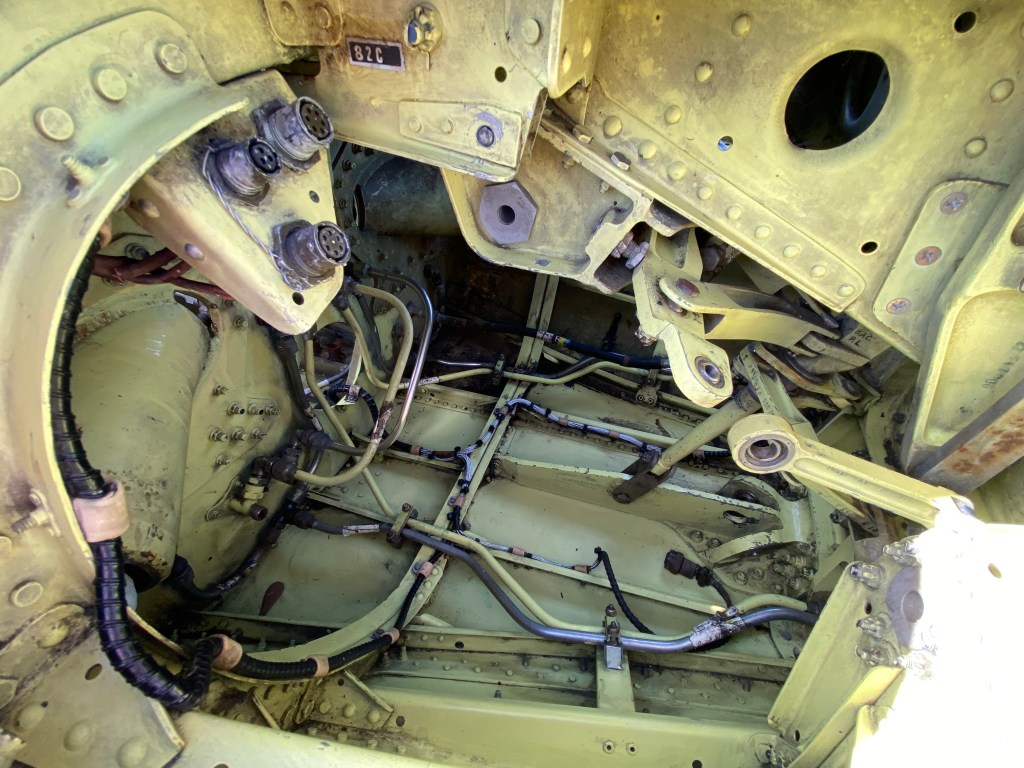

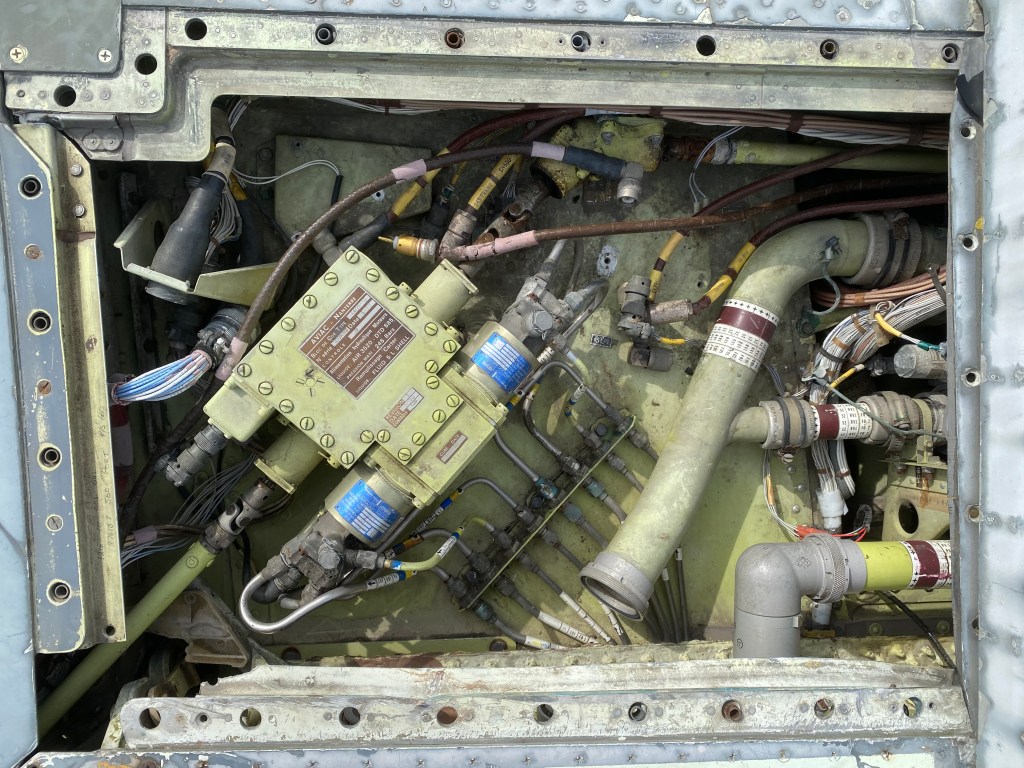

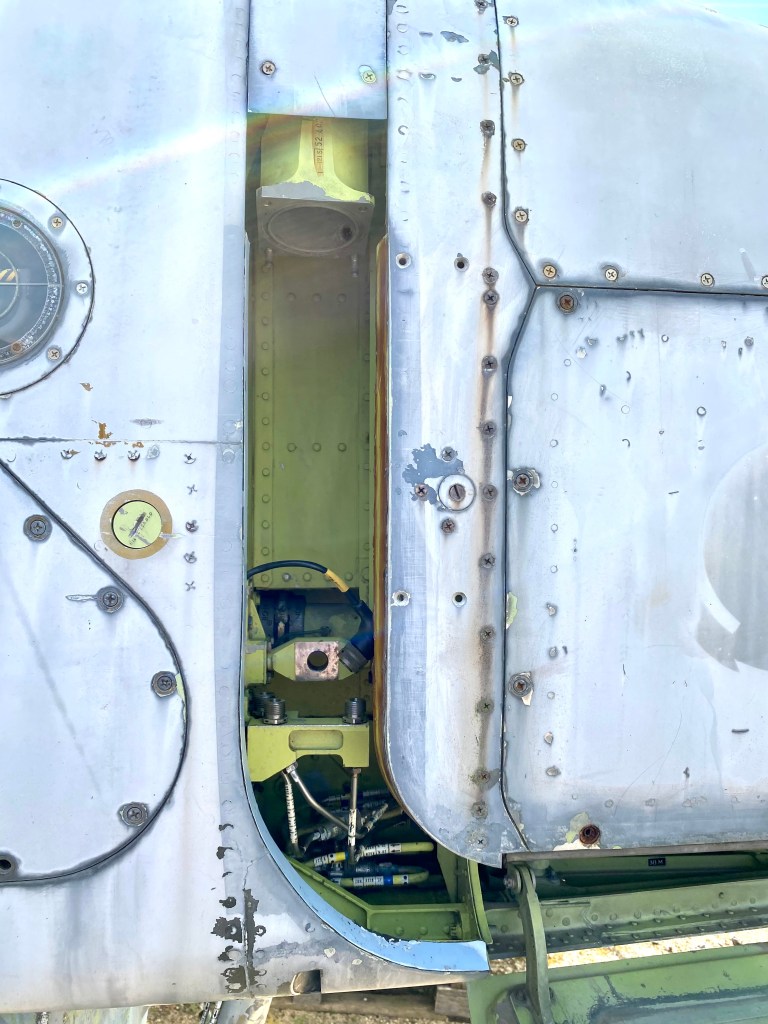

JULY ’23 UPDATE: This month’s focus has mainly been centred around the LH engine bay. The door was removed in June following the completion of the RH ‘engine’ installation and an initial inspection of the components left on the LH side revealed that there were some hydraulic parts missing on the front engine bulkhead, as well as some pipework.

These valves and pipes were all sourced and refitted.

I thought I’d got everything I needed but discovered that I’d missed one small pipe, so it was back to the parts manuals and then a root through my spares boxes to discover that amazingly I had the exact missing part squirrelled away.

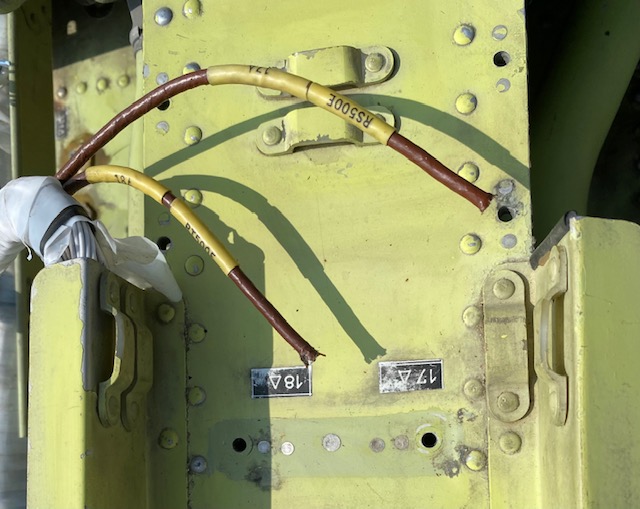

Similar to the RH side engine bay, the engine door fire wire electrical connector was heavily corroded so has been replaced.

In terms of the rest of the bay, the electrical connections to the engine are in a far better state on this side (on the RH side the connectors had just been chopped off whereas on the left they are all still there (ready for an engine to be fitted!!). Many of the P Clips on the pipes and wiring had rusted similarly and these have all been changed out for new.

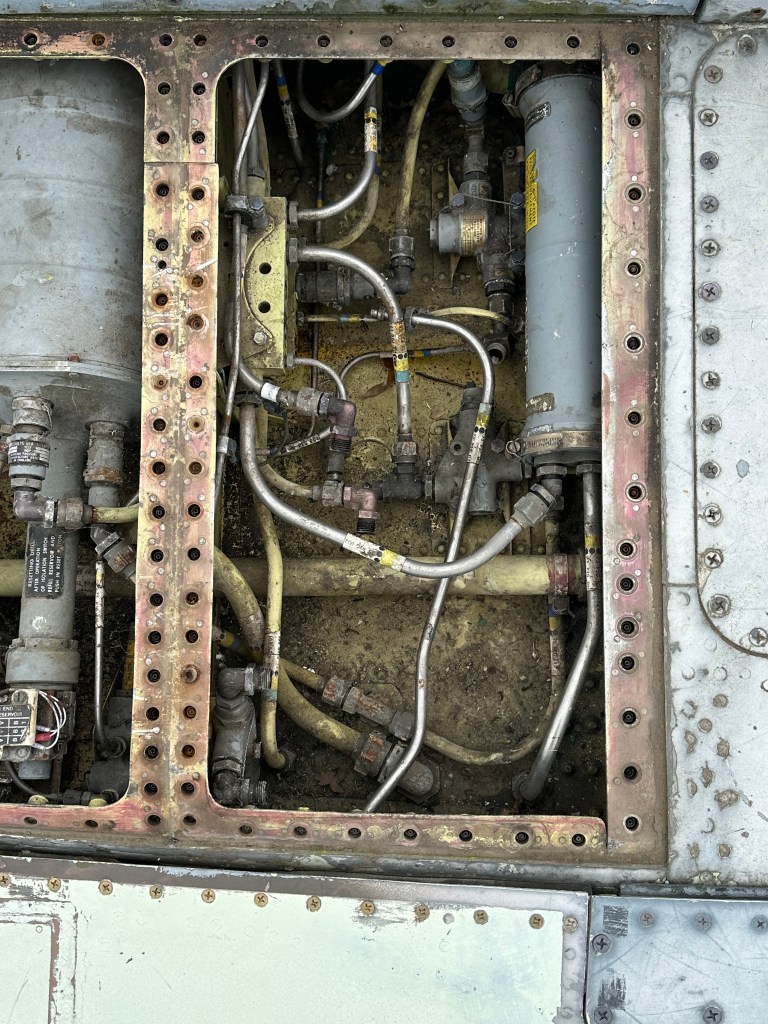

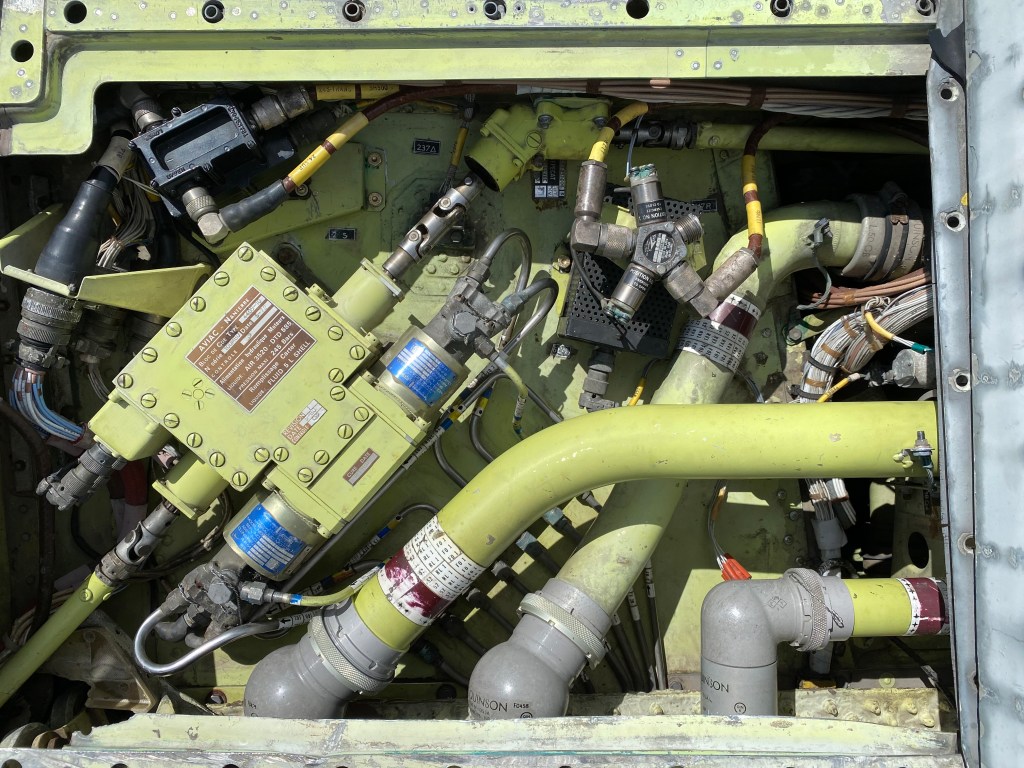

With the hydraulics installation in the engine bays now back together focus will move on to the other areas where I know pipework is missing to get the system complete. I still need to refit hoses to the PFCU’s to the tailplanes and rebuild the rudder PFCU system. The pipework out to the mainplane on both sides also needs rebuilding and the hydraulics bays on top of the fuselage both need a massive clean up – at some point.

Plenty to do in these bays but I have located all the missing pipework as well as the rods for the flaps.

More on progress in these bays to come in the future.

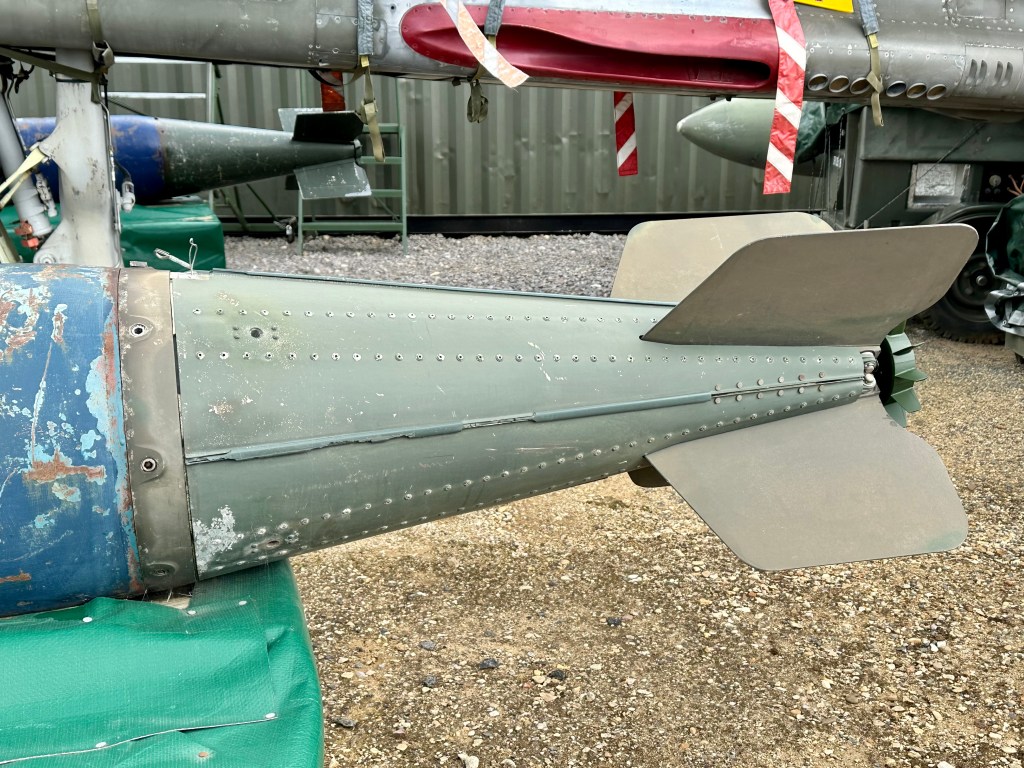

On another front I’d been on the lookout for a second tail for one of our 1000lb practice bombs for quite a while. Previously I’d located and fitted one Mk117 retarded tail and this month a Mk114 freefall tail appeared for sale relatively locally. A deal was duly done and the tail collected although it had had quite a tough life with the fins pretty heavily damaged.

Back to some good old fashioned tin bashing and riveting and things were brought back into a decent degree of straightness (compared to where we started).

The tail was then fitted as well as an arming vane, that was previously missing, on to our first tail.

Back in engine world and pretty much all of the parts to assemble the LH back end have been brought together at Enstone and now assembled using our experience with the RH side as template. I still have one element to source but this should be sorted fairly shortly and I’ll then get this side hung in place and the door refitted.

And that pretty much rounds up progress on the aircraft for this month.

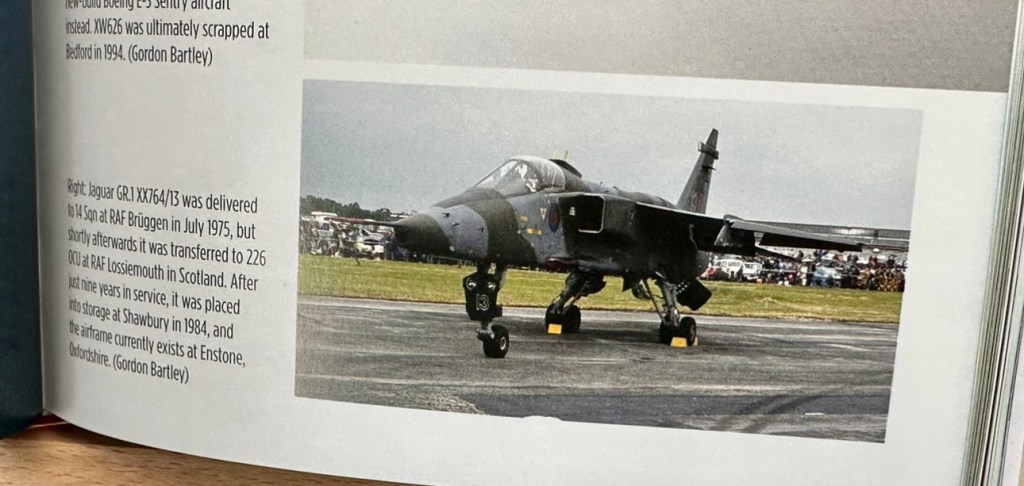

Early in July I spent a few days at the Royal International Air Tattoo just down the road (ish) from Enstone at RAF Fairford. Obviously the Jaguar presence was pretty much zero but XX764 did make a very (very very) small appearance when I found a picture of the aircraft in a book on sale on the Runway25 stand (www.runway25.com) on the history of the Woodford Airshow.

And finally, a quick welcome to new followers of this page and the project. Remember that previous monthly updates can be found on the ‘Archive News’ tab at the top of the page.

This year’s Open House Day date has been still on for Saturday the 16th of September, and we’ll hopefully be able to welcome you to Enstone to catch up on progress with the the aircraft. Many thanks to those that have already registered to attend.

As usual it would help us immensely for you to pre-register your interest in attending (there’s no charge for coming) as it will assist us with parking, catering etc.

To register for an e-ticket please visit this link: https://www.eventbrite.co.uk/e/xx764-2023-open-house-registration-640854612397?aff=oddtdtcreator

As always, many thanks for the ongoing interest and support.

Neil

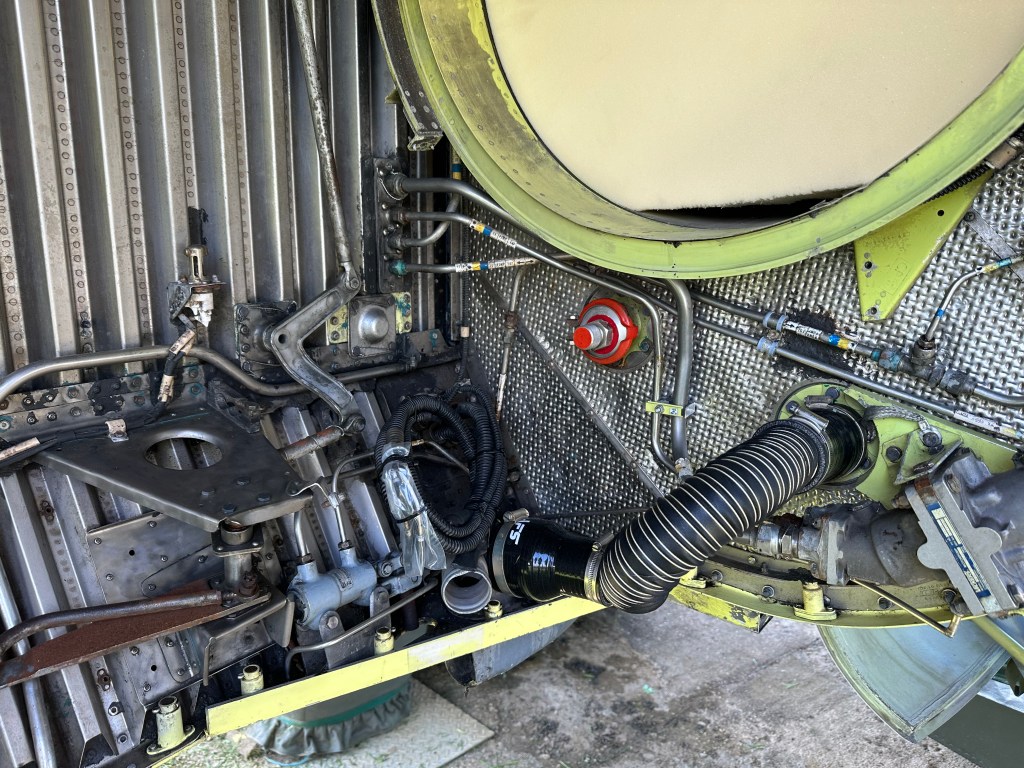

SPRING ’23 UPDATE: Firstly, apologies for the massively overdue update. Work has overtaken this Spring and progress on the aircraft had to take a back seat. That said we were able to move some tasks on and have rebuilt the RH engine bay with the Adour backend that we started to assemble earlier this Spring.

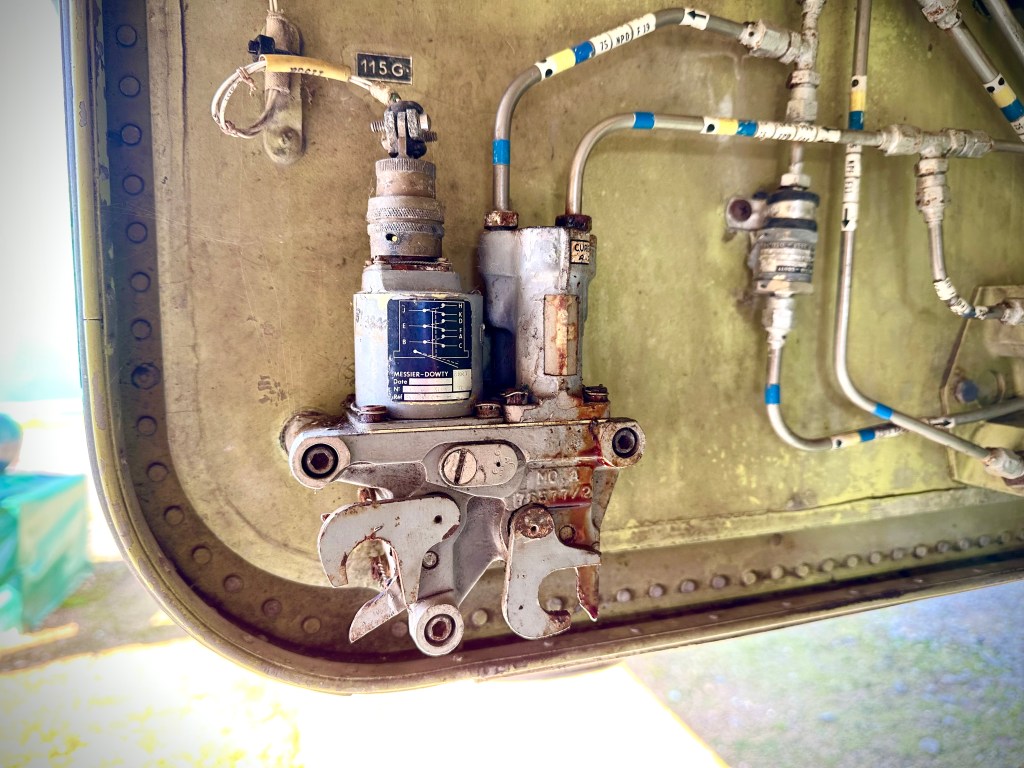

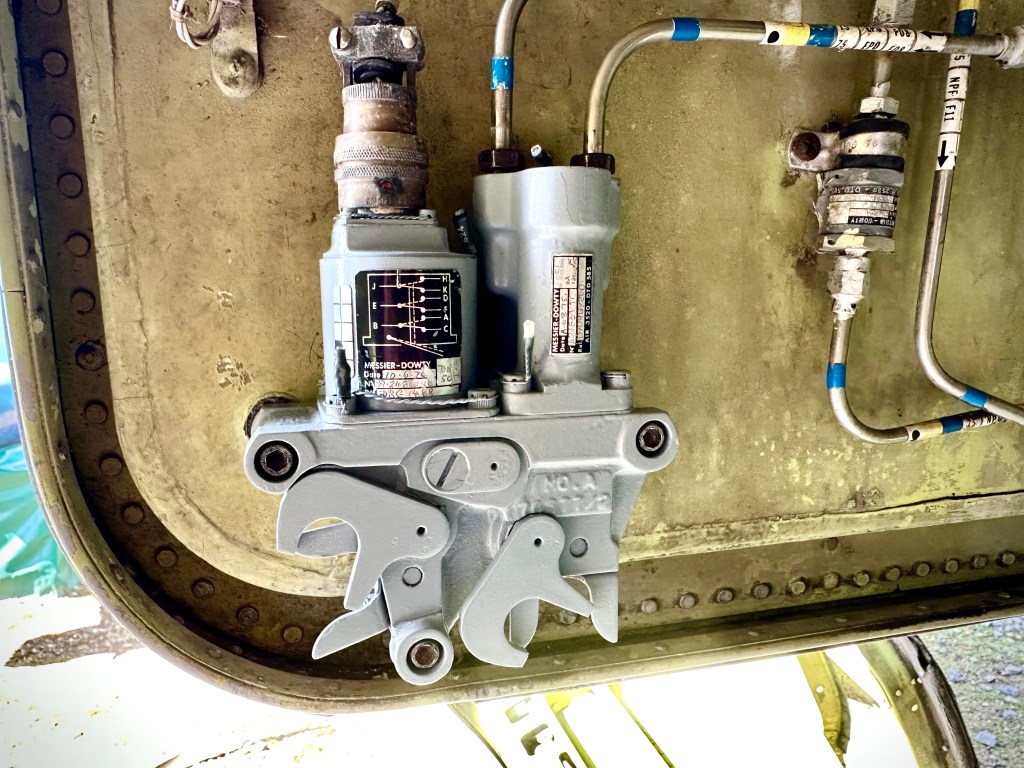

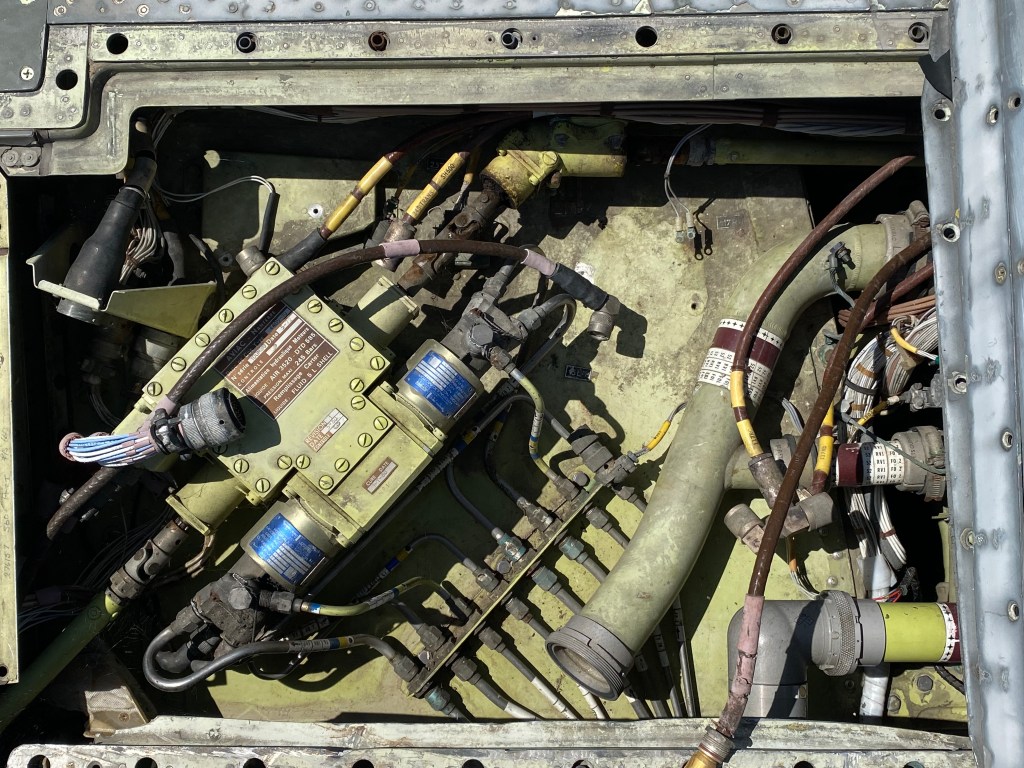

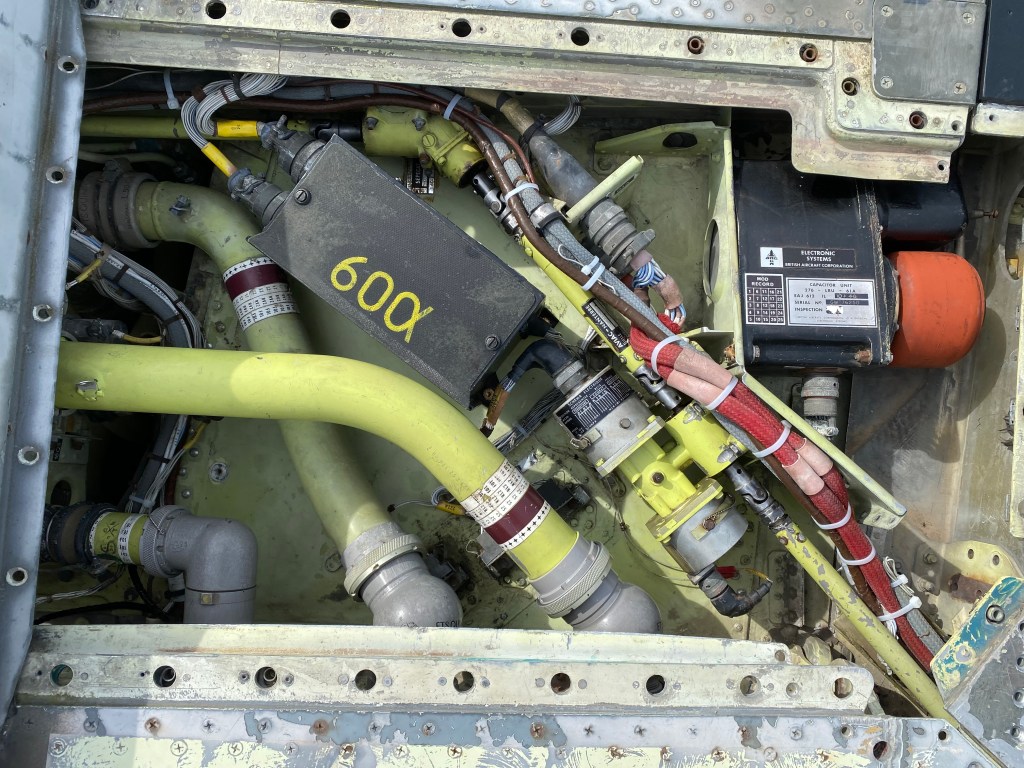

Part of the right hand engine bay works involved replacing missing hydraulics component on the forward engine bay bulkhead. All parts had to be sourced with the original parts having long been removed by the previous aircraft’s owners.

The RH engine bay door had a good cleanup.

The fuel feed pipe was blanked and Air Producer output pipe diverted to exit through the Alternator Cooling vent. If I do eventually get the Air Producer running I don’t want to have the air just venting into the engine bay.

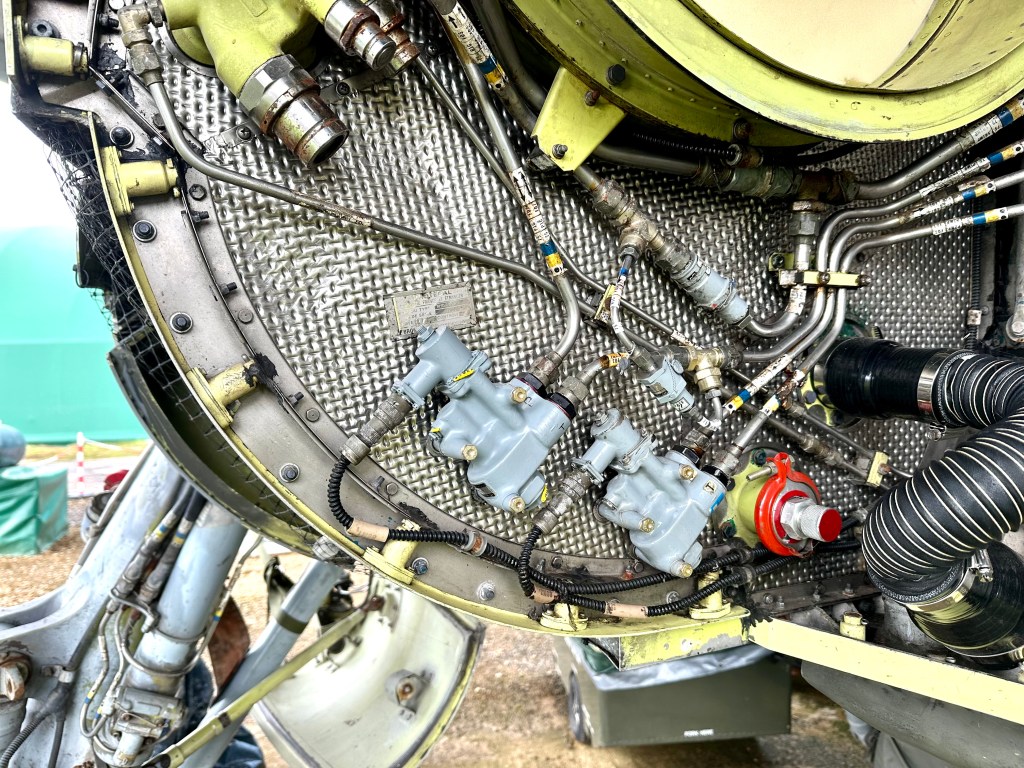

Eventually all the parts were assembled and the back end hung in position. The ‘engine’ is complete through from the mixer module aft.

And with the door refitted the look is complete. I’m pretty happy with the way it has worked out.

The finishing touch – cover fitted.

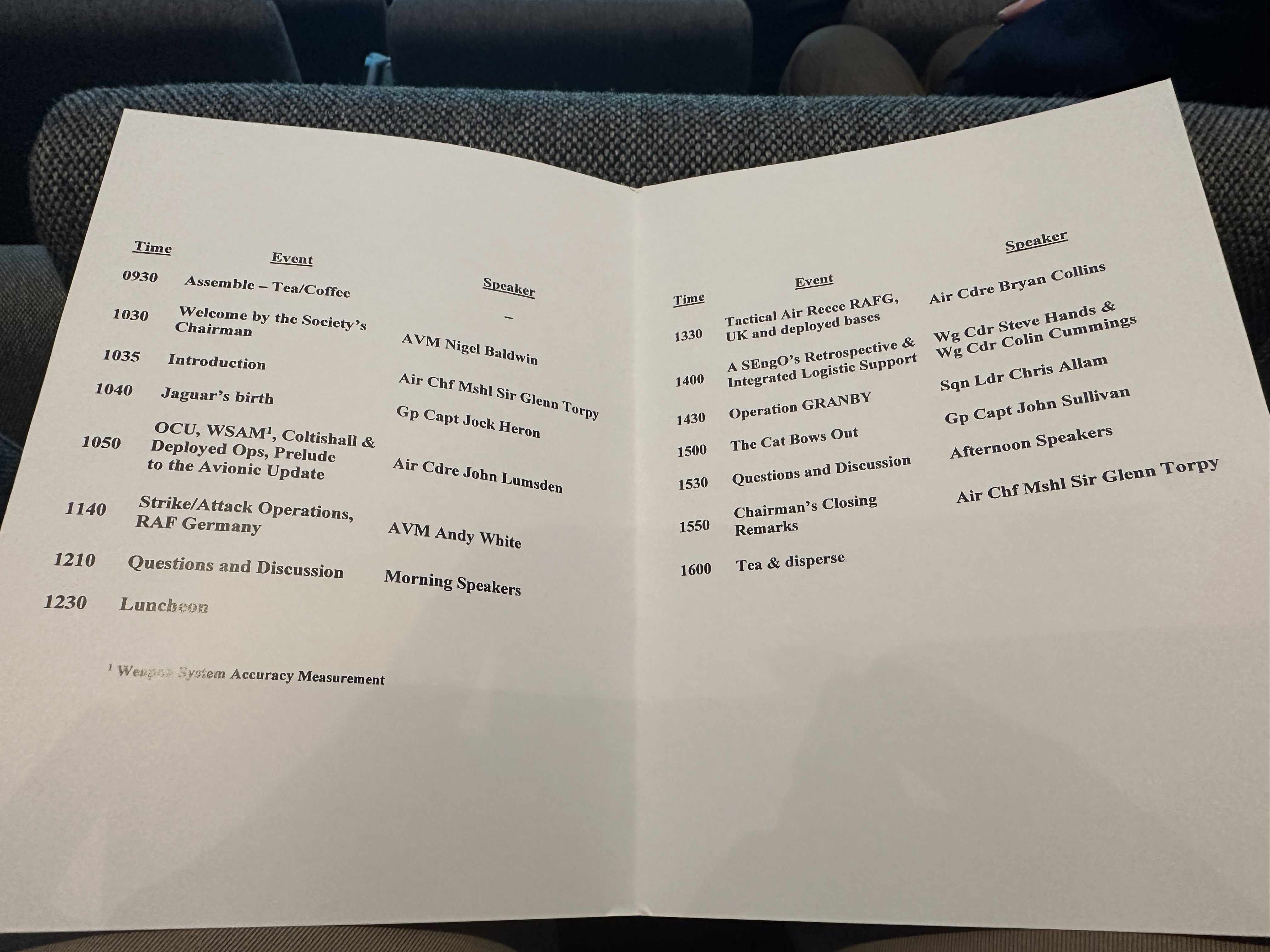

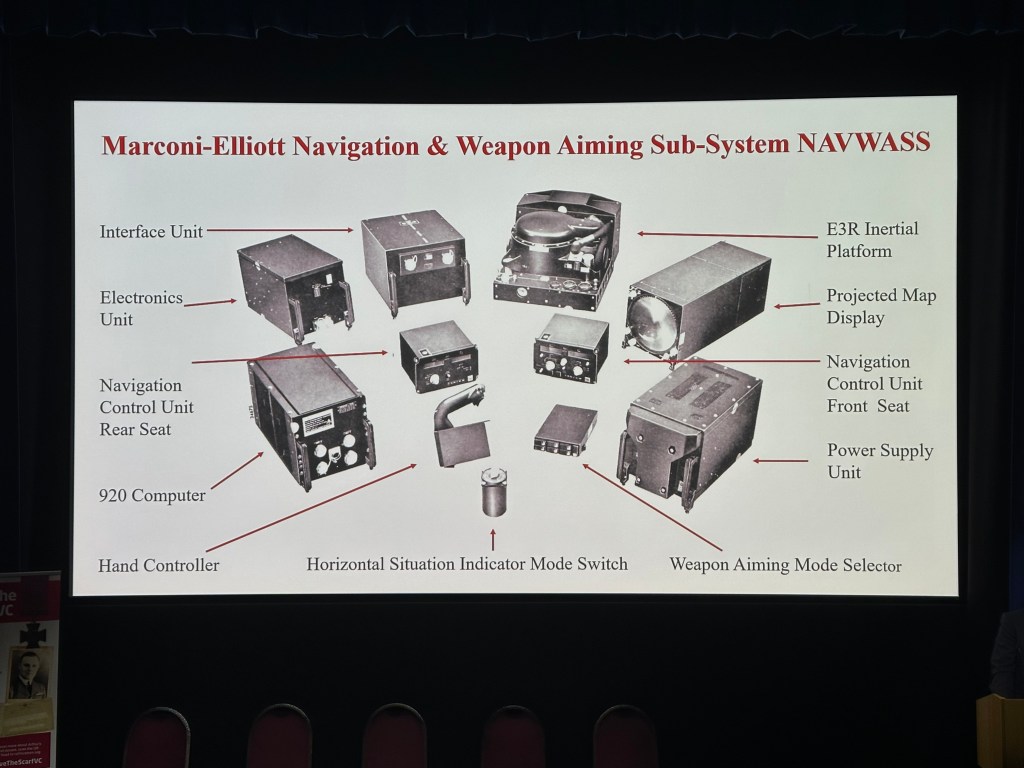

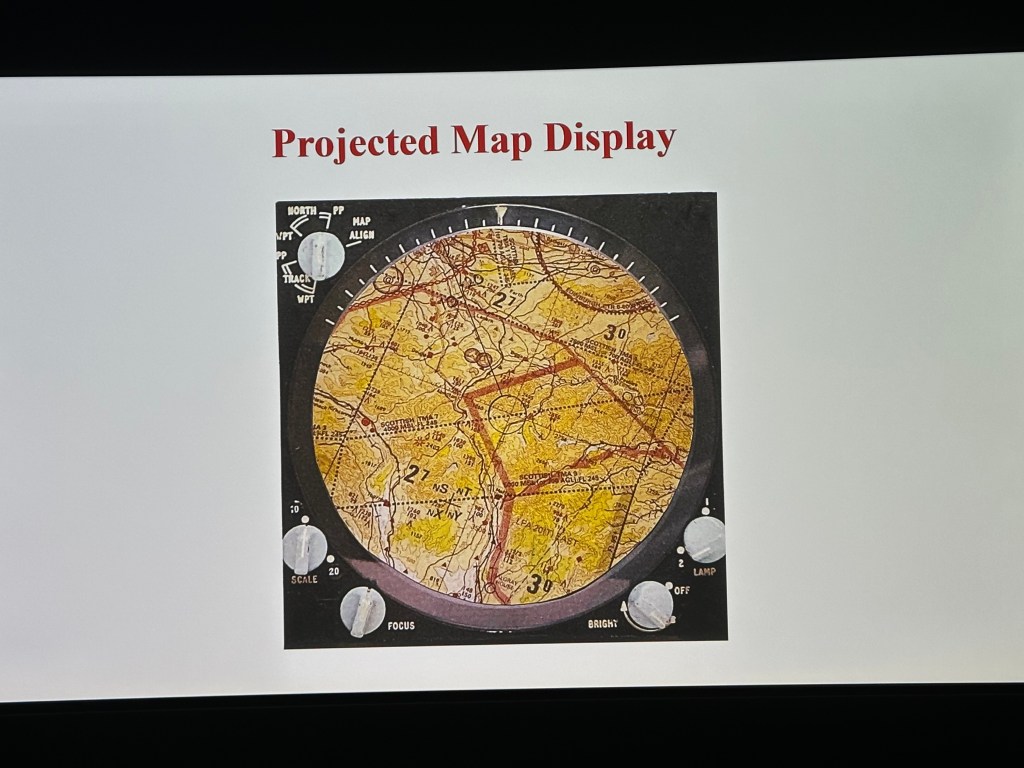

In April I was lucky enough to attend a day of presentations at the RAF Museum Hendon hosted by the RAF Historical Society on the Jaguar In RAF Service. The audience were treated to some enlightening talks and anecdotes by various Jaguar ‘royalty’ invited speakers.

Back at Enstone a few further tasks have been ticked off the ‘to-do’ list.

The LH Main Gear Door unlock valve was replaced by a new-old-stock part.

A CBLS has been located and purchased – another restoration project to add to the list!

And finally the LH engine door has been removed in order to replicate the installation on the RH side.

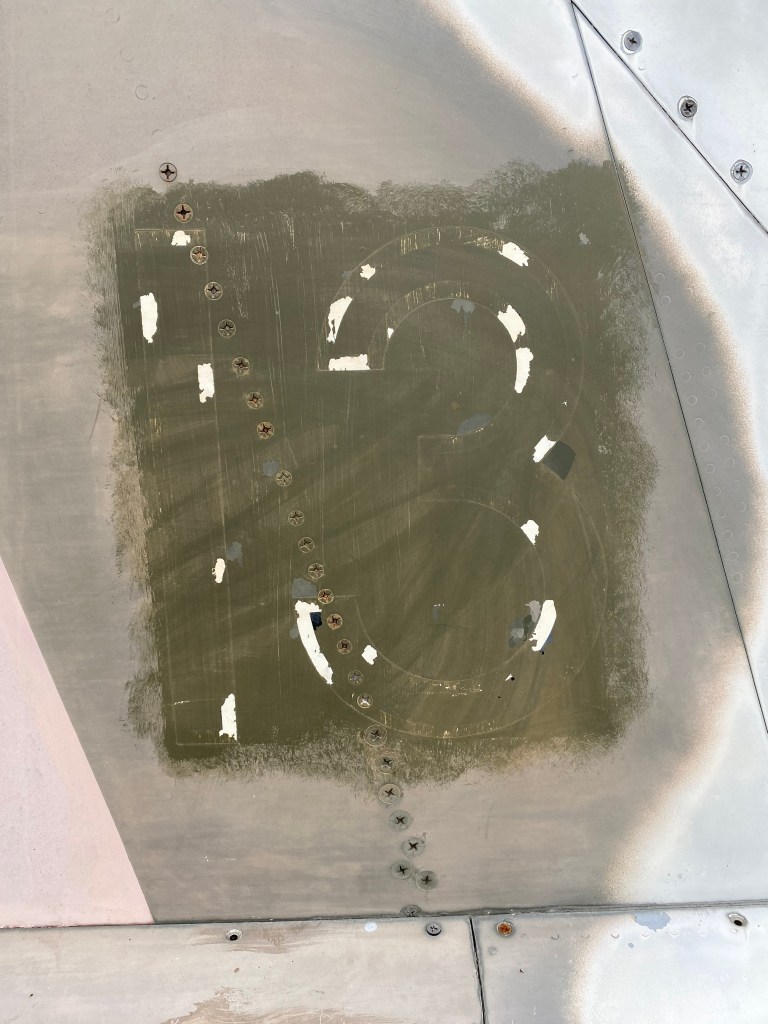

As a quick reminder, this year’s Open House Day date has been set for Saturday the 16th of September, hopefully we’ll have better weather than the day pictured above, caught by Enstone regular Ian Meadows.

As usual it would help us immensely for you to pre-register your interest in attending (there’s no charge for coming) as it will assist us with parking, catering etc.

To register for an e-ticket please visit this link: https://www.eventbrite.co.uk/e/xx764-2023-open-house-registration-640854612397?aff=oddtdtcreator

As always, many thanks for the ongoing interest and support.

Neil

MARCH ’23 UPDATE: Only a very brief update this month. I was out of the UK for two weeks with work early in the month and the focus this month has remained pretty much solely in the starboard engine bay.

The aim here is to recreate the rear end of the engine using real Adour components from the burner ring aft. Forward of this will be blanked.

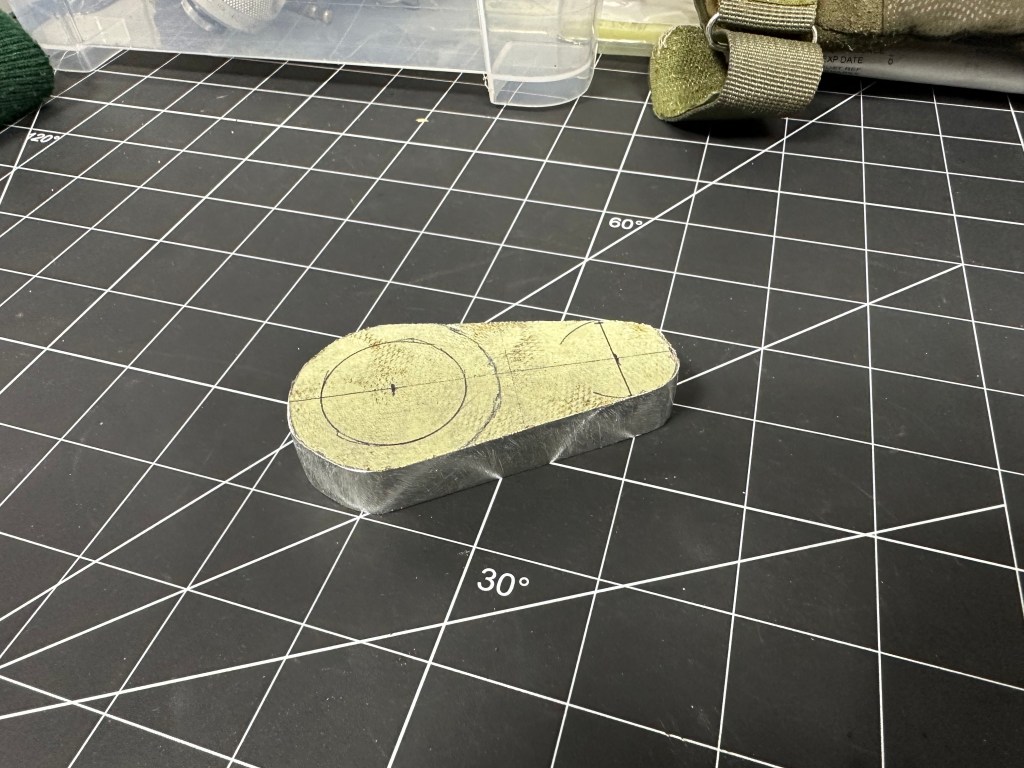

With one set of components brought together at Enstone the various elements were assembled. The nozzle actuator ring and rods will sit in a fixed position so there is no need to locate nozzle actuators, brackets have been fabricated to secure the rods in position.

The ‘engine’ section will locate on the rear engine hanger and I’ll set the nozzles to an intermediate setting to a representative position.

Whilst the door has been off it has also been the first time since I acquired the airframe to give the engine bay a thorough clean up. All the rusty P clips have been replaced and a foam blank has been sourced and fitted at the aft edge of intake tunnel.

Unfortunately, heading into April, my work schedule gets even more hectic, so progress in the coming few weeks will pause again. The aim for early May will be to get the starboard bay complete, the exhaust section in place and th door refitted before starting on the port side. I have pretty much all the parts in hand to get both side to the same level.

Apologies for the brevity of this month’s update, unfortunately all this progress (however limited) still has to be paid for and my work schedule has to define what and when I can get further tasks completed but as always, many thanks for the ongoing interest and support.

Neil

FEBRUARY ’23 UPDATE: With, hopefully, the worst of the winter weather behind us (although as I write, snow is forecast!) February has been a month to kickstart some tasks back on the aircraft.

Picking a dry day I opened the cockpit up for the first time since the end of the Autumn last year. The cockpit had stayed dry (I’d double layer covered the canopy over an original set of Jaguar canopy/windscreen/electrical bay covers that stay on the aircraft all year).

Whilst the covers were off I added a set of Bluetooth temperature and humid sensors to the cockpit, electrical bay and laser bay to allow me to remotely monitor the various areas. I’ve also added a small dehumidifier to the cockpit with the wiring and water drain routed though the cockpit pressurizing vent on the seat bulkhead (and the hole filled around the pipe and wiring)

A set of caps for the external hydraulic connectors have been sourced (the originals having long gone).

After a quick clean up they have been fitted with lock wire tethers.

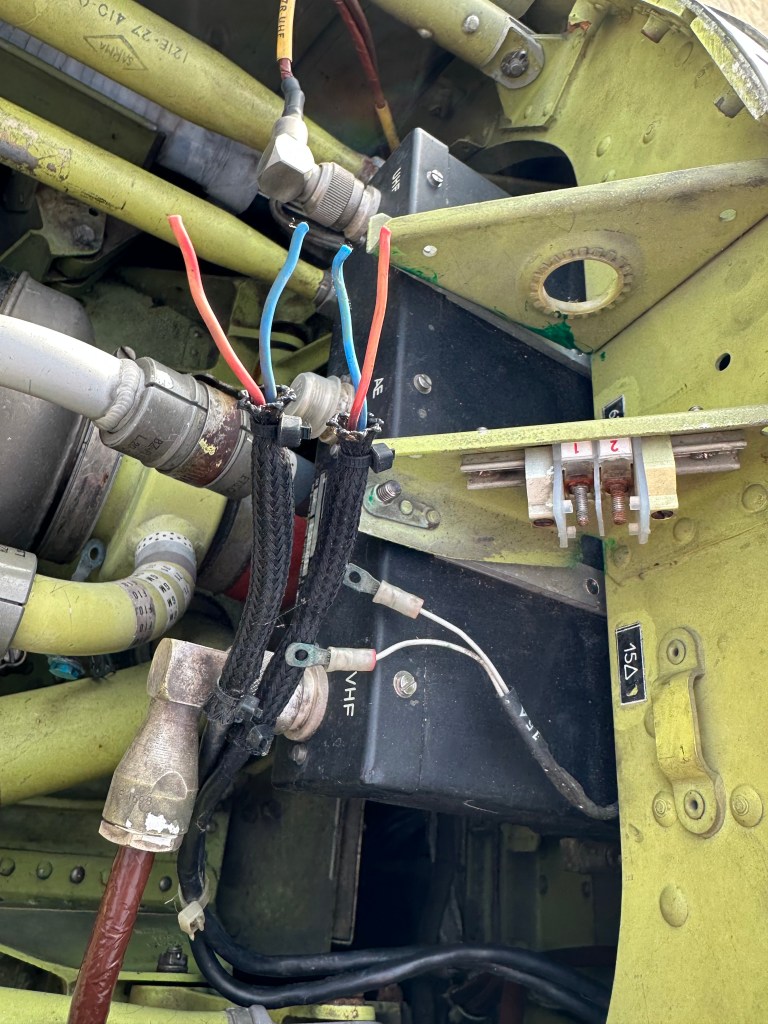

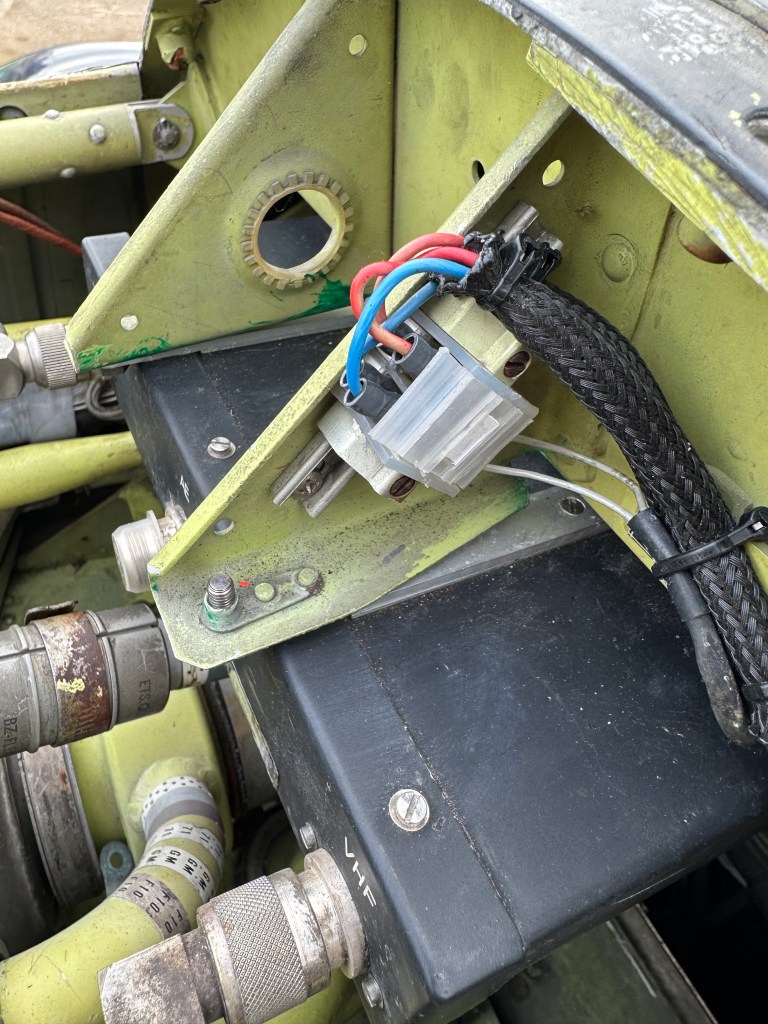

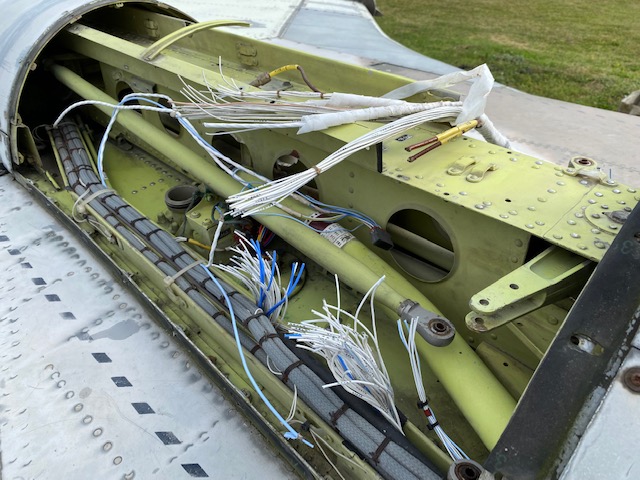

Up in the forward spine area a missing terminal strip for the wiring controlling the aerial switching unit has been sourced and fitted.

After locating a Matra M155 rocket pod nose late last year I have now been able to source a centre and tail section as well as an inert rocket as an example piece. These have now been assembled.

The big task for this month has been to make a start on the starboard engine bay clean up and preparation for fitting the engine back ends that I have ‘in stock’.

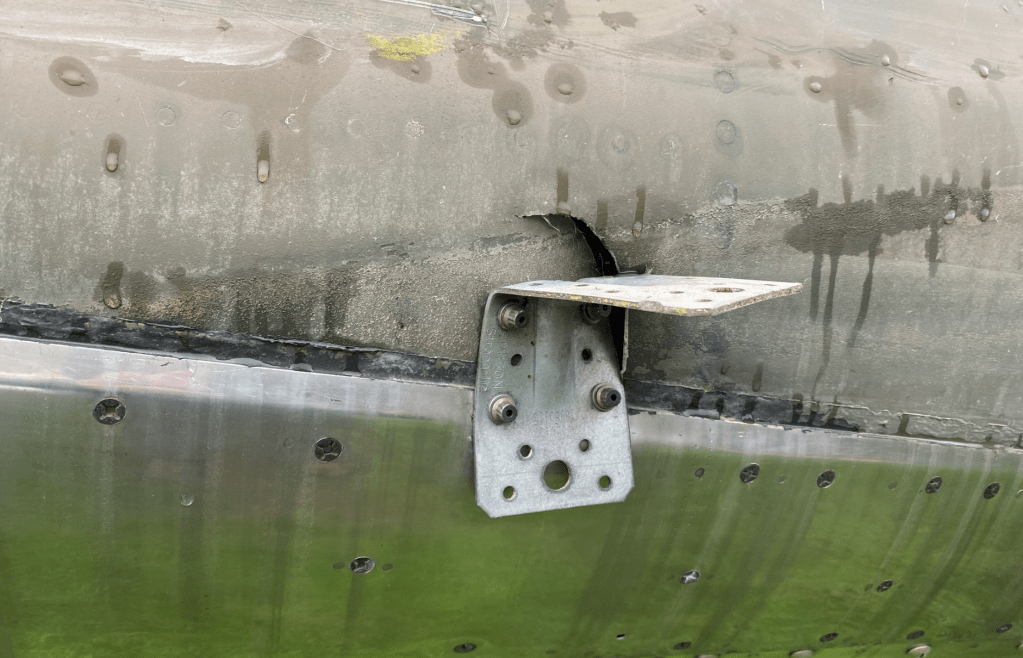

Getting the door off was a pretty monumental task.

I’ve relocated the hardware to Enstone now and am looking into how it will be mounted.

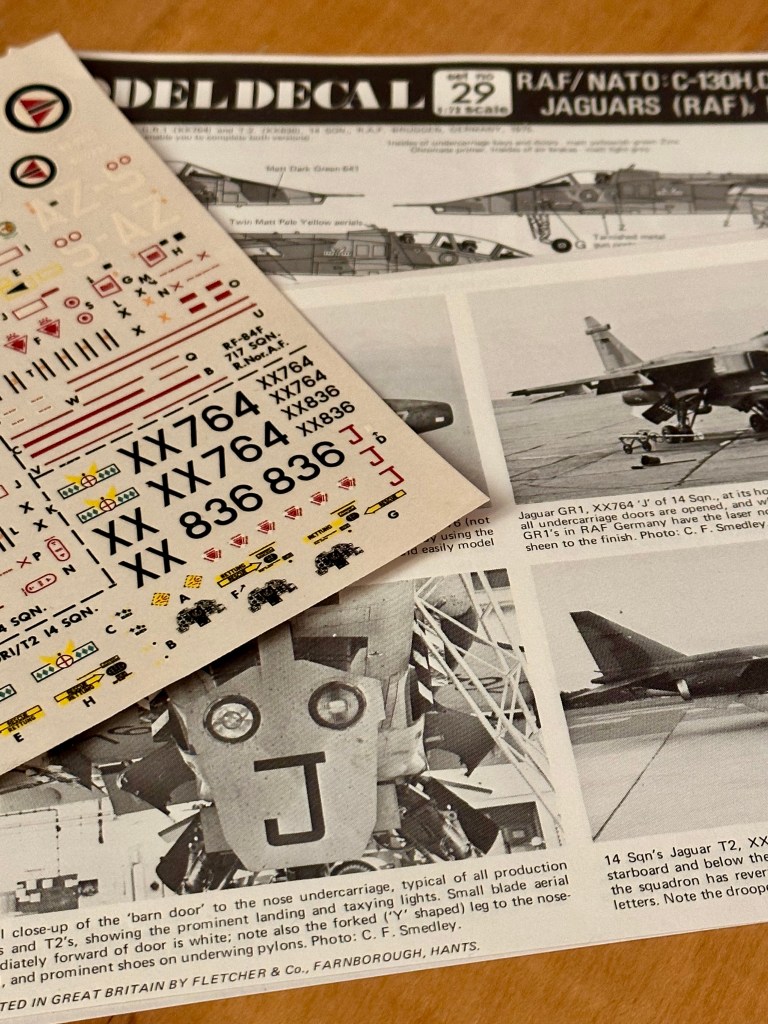

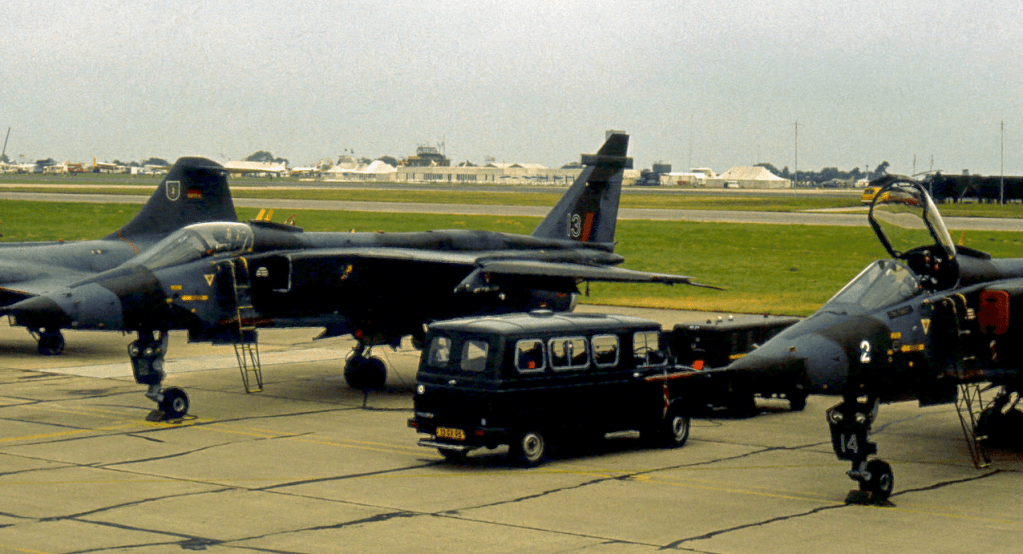

And finally, in slightly less aircraft related news, I found a set of modelling decals on eBay that include markings for XX764 when it was on squadron with 14Sqn in Germany just after the aircraft delivery.

As always, many thanks for the ongoing interest and support.

Neil

DECEMBER ’22/JANUARY ’23 UPDATE: A combination of factors at play in December and into January mean another double month update. For February I’m aiming to get back to the regular monthly page updates. Here in the UK December brought a cold snap and January has been very wet, neither of which have leant themselves to advancing many tasks on the airframe.

One small task that did get ticked off the to-do list in December was the replacement of the port outboard gear door actuator. At some point in the aircraft’s past the actuator coupling to the door had been removed and I had a spare in my stock of parts.

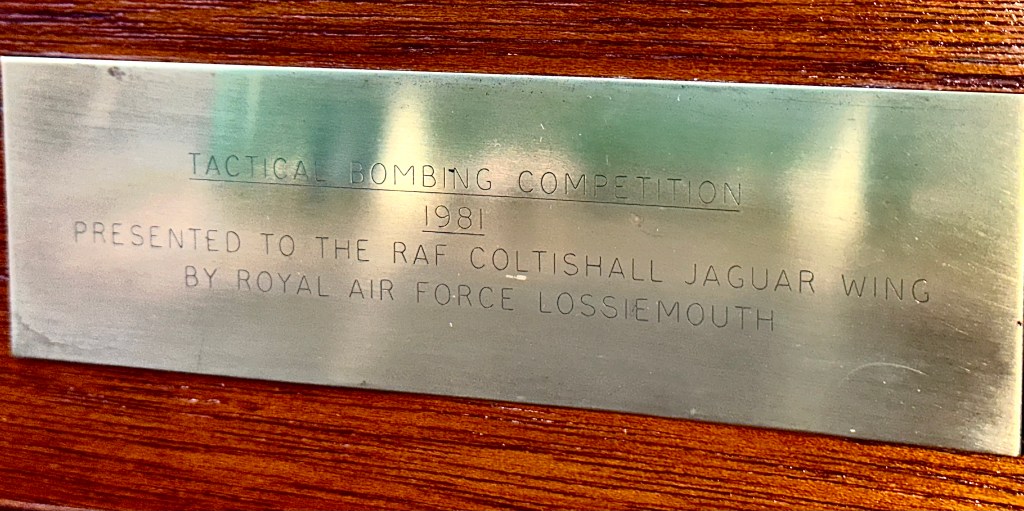

Also, just before Christmas I came across this trophy on a well known auction website. Presented by RAF Lossiemouth to the RAF Coltishall Jaguar Wing for their participation in the 1981 Tactical Bombing Competition.

December’s cold weather did give any opportunity to capture some images of the aircraft with some seasonal frost and snow.

As it’s the end of 2022 it’s an opportunity to look back at some of the areas that I’ve managed to progress over the course of the year.

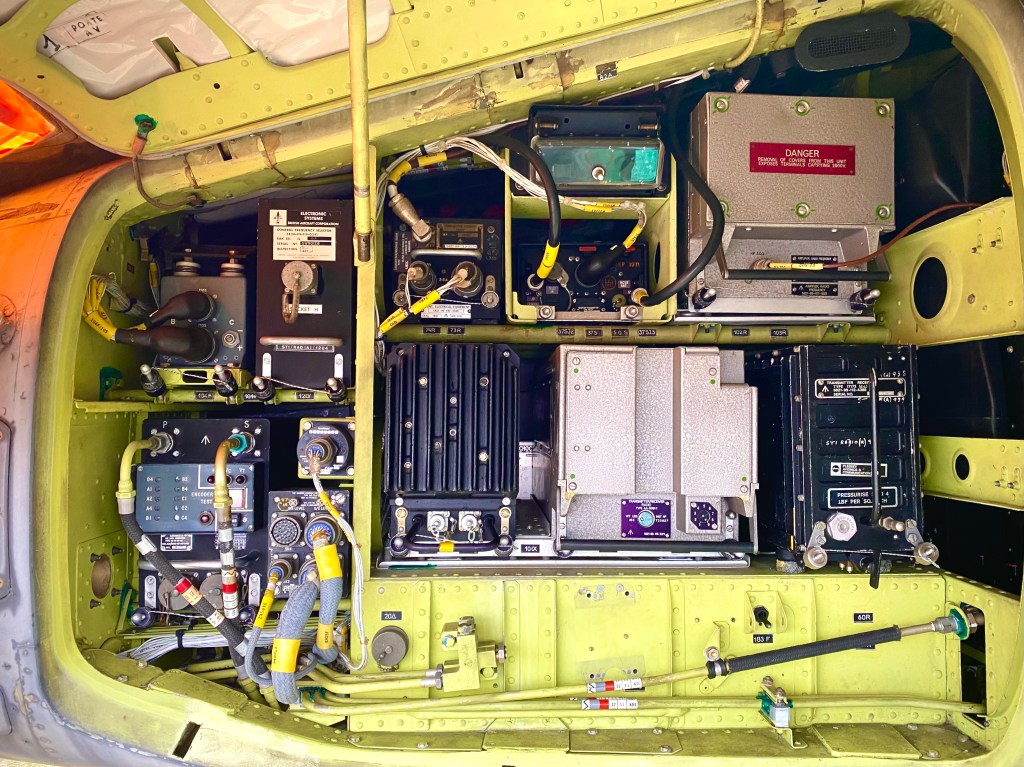

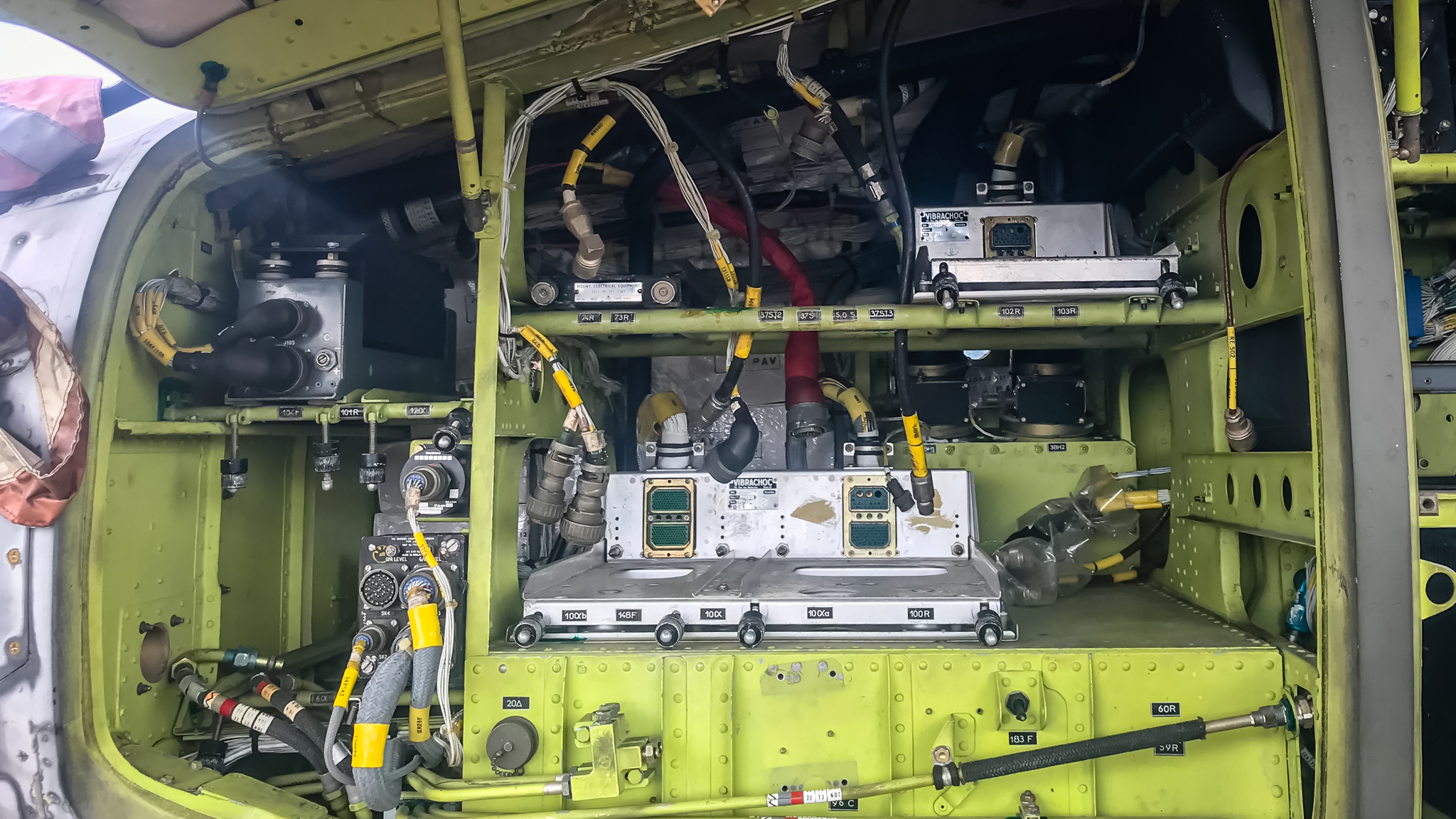

Early in the year I managed to source two of the avionics units that had been long term residents on the missing parts lists, a TACAN Transceiver and an Air Data Computer.

With the ADC installed this has pretty much finally completed (cosmetically at least) the forward avionics bay, something I wasn’t sure I’d be actually able to achieve. Looking forwards, the next step will involve powering some of these units up…..

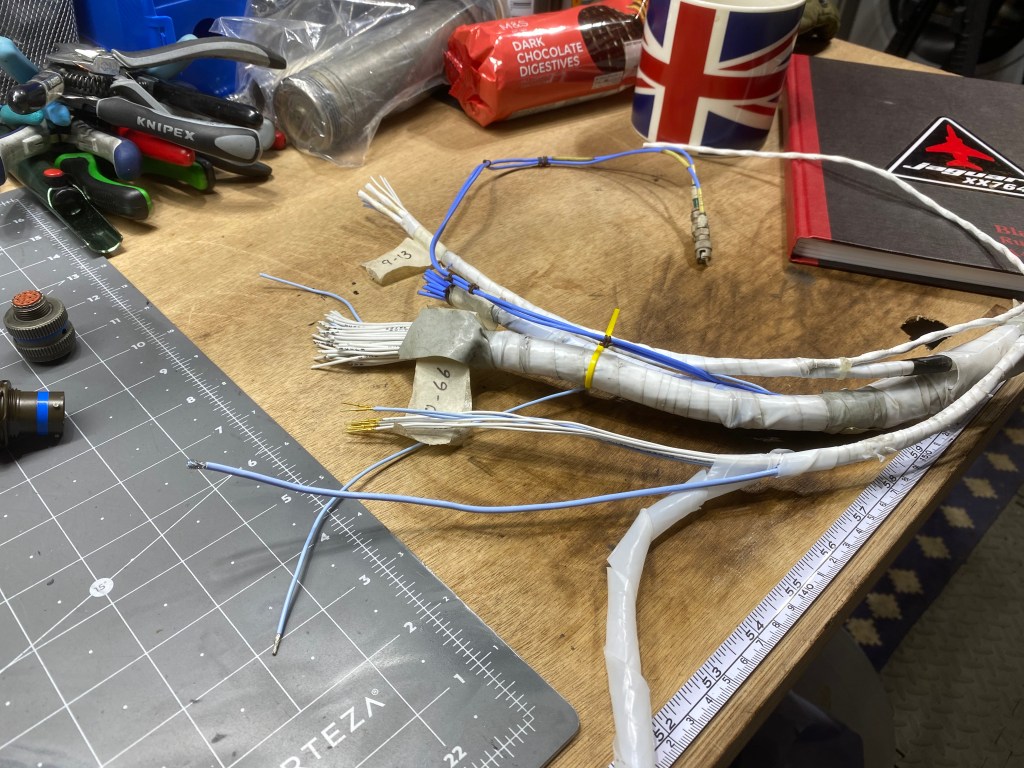

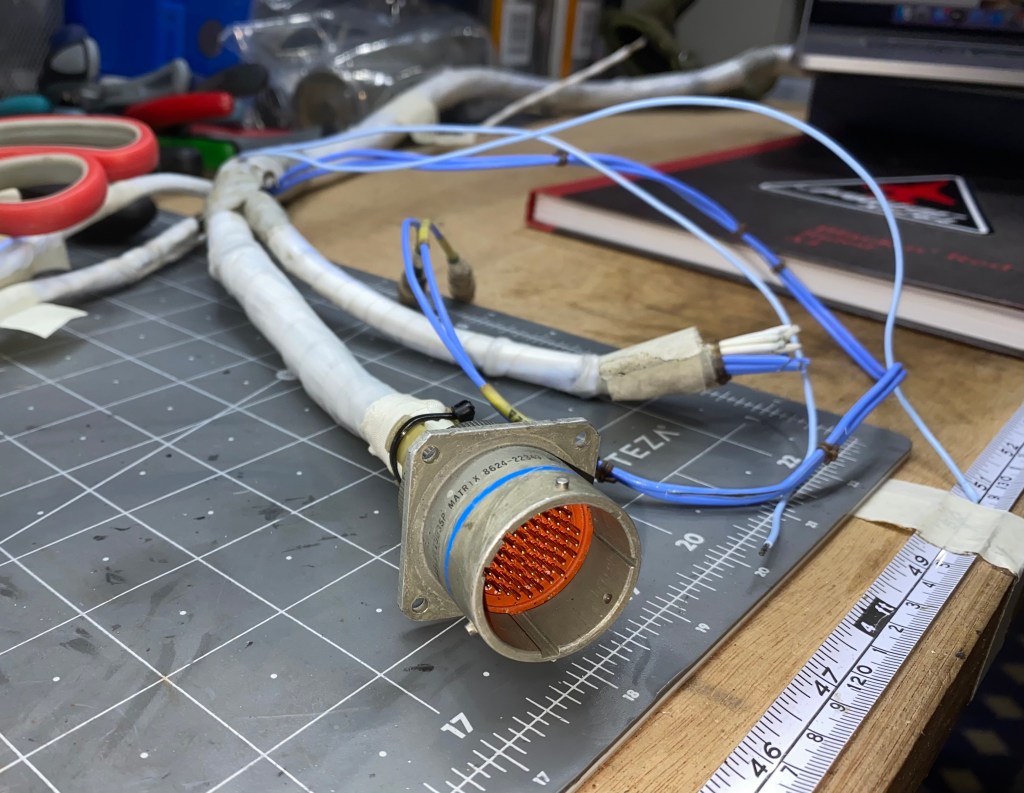

More progress has been made in the repairs to the spine harness. The harness itself has been now pretty much fully terminated into connectors at all the cut points, I now have the same repairs to make to the airframe side.

The previously installed Laser Electronics ballast unit in the lower nosebay has been replaced by a real unit. Target acquired!!

The Mk117 retarded bomb tail was fitted on to one of our 1000lb practice bombs.

The forward upper equipment bays have had a thorough clean up and been repopulated with all the missing parts. Still have some wire locking to complete and bonding leads to fit but again, cosmetically, the bays are complete.

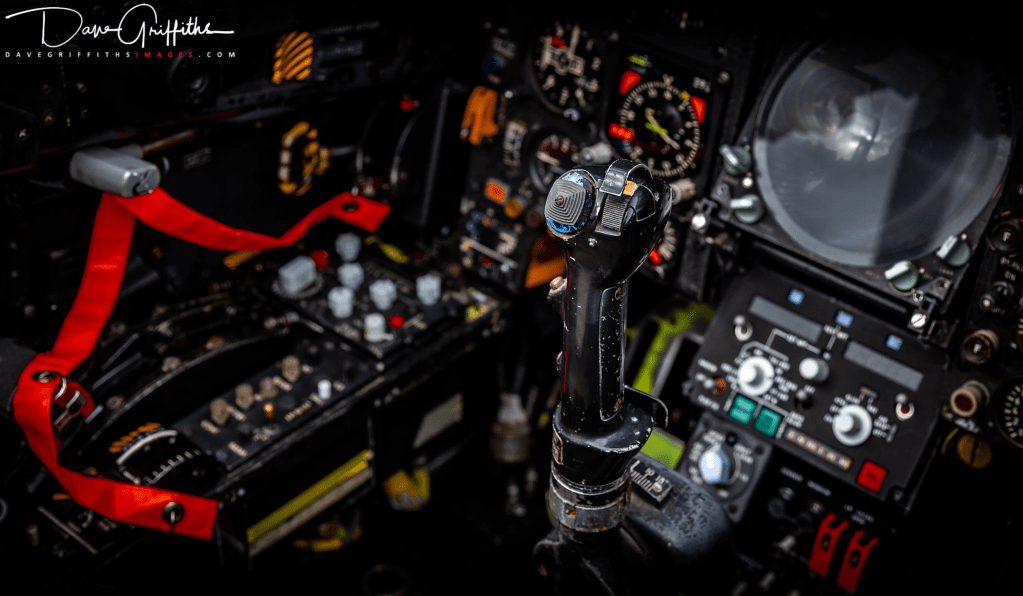

A new-old-stock stick top has been fitted.

Another missing part for the cockpit was also sourced this year, a HUD data recorder unit.

Externally, the missing incidence probe, another long term entry on the missing parts list, has been sourced and fitted.

There has been plenty of progress at the rear of the aircraft this year. The tailplanes that were removed previously had some attention to the dents and dings, tasks easier carried out while the control surfaces were on the trestles.

In preparation for refitting the tailplanes the new pair of C Levers were prefitted and all the hardware for fitting the tailplane PFCU’s was kitted.

With the C-Levers prepped and the repairs to both the tailplanes and fuselage complete it was time to refit the tailplanes and all the missing internal hardware.

Pre-installation the rear fuselage looked like this:

And after plenty of cleaning and with the hardware refitted:

And finally the tailplanes were refitted:

In the spine I have started rebuilding all the missing air conditioning hardware. There is plenty more to do here but it’s a reasonable start.

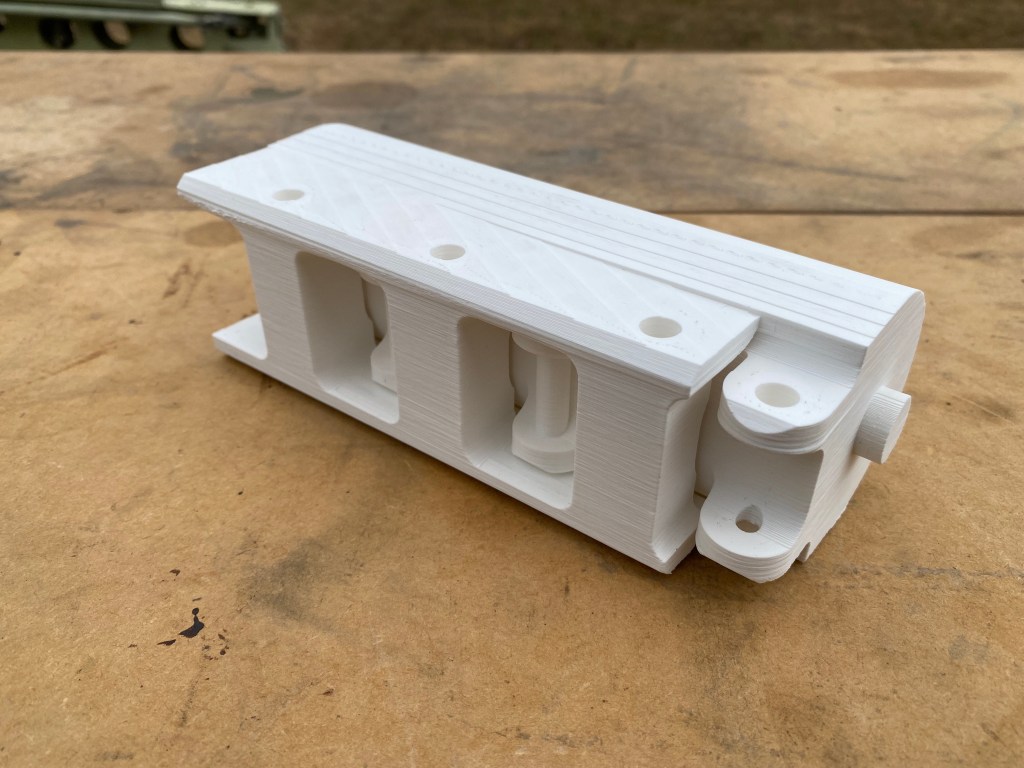

On the fin the missing rudder damper has been replaced by a 3D printed replica and the missing bracketry fabricated. Although obviously non-functional it fills the hole and from the ground visually looks OK.

In terms of Ground Support Equipment, this year I have sourced a Hydraulics rig and weapons loader. Both need some attention but these will be more for the long term and are not immediately required to be serviceable.

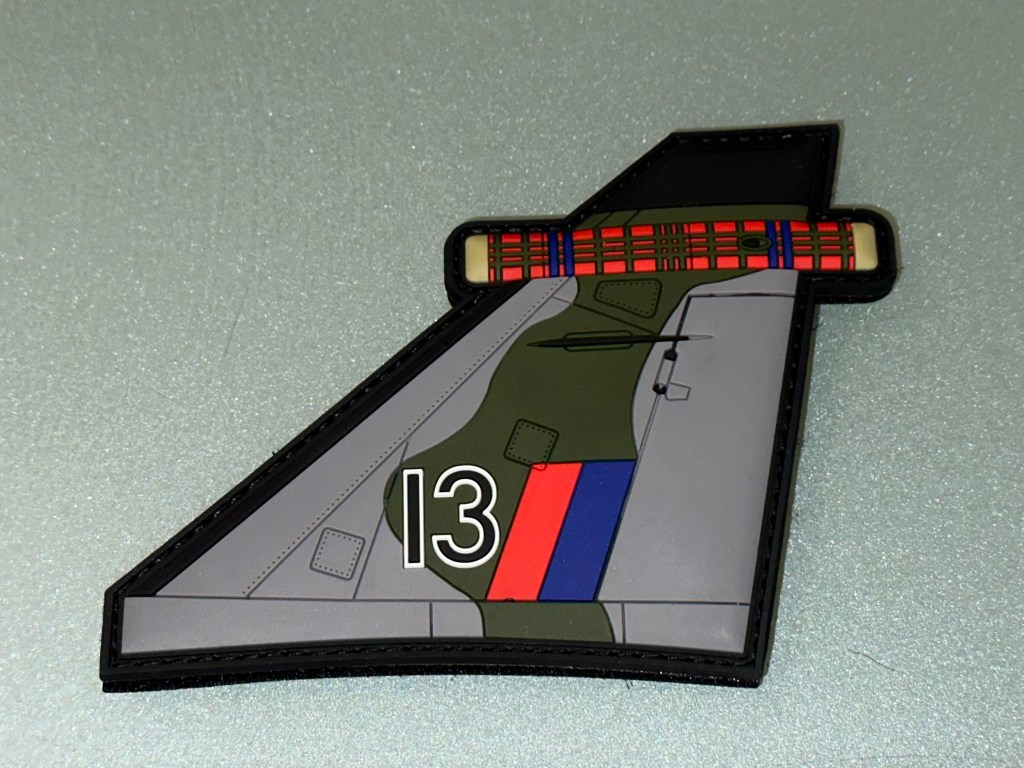

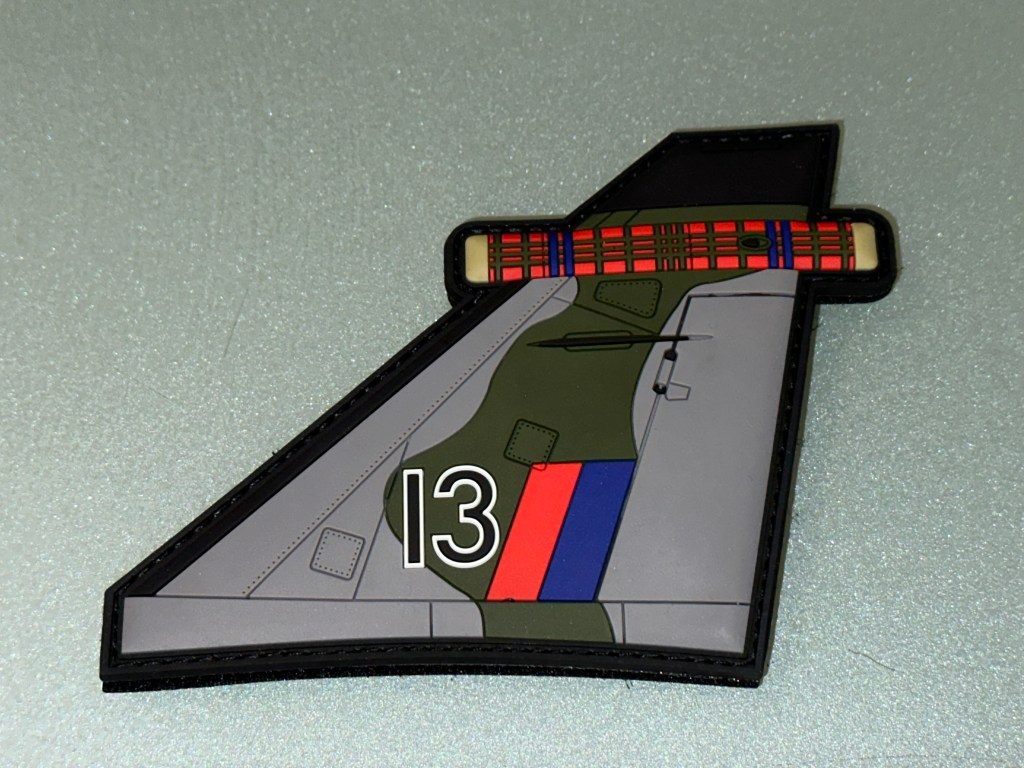

I’ve made several additions to our merchandise range this year. It is now possible to build a miniature version of XX764 with a stylised resin Jaguar kit. We have also added caps, beanie hats, bottle openers, PVC fin patches and a high end digital render print to the range, all of which can be found on the ‘Merchandise’ page.

Looking forwards to a few aims for 2023 nothing is written in stone – if some of these don’t happen it’s not the end of the world.

AIRFRAME:

Continue with panel removing, area cleaning and assessing/replacing missing parts where possible.

Rebuild rear end hydraulics (pipework to tailplane PFCU’s)

Fit a Rudder PFCU and associated hydraulics.

Reinstate hydraulic lines to flaps/spoilers.

Try and repair/replace spine Teleflex’s to Arrestor Hook and Brake Chute release mechanisms.

Continue with spine air-con and fuel pipework rebuild.

Remove engine doors, clean bays, assess bracketry required to hang burner rings and nozzles.

Cleaning of Air Producer bay (refit Air Producer maybe), possibly refit the air brakes when this is complete.

ELECTRICAL:

Troubleshoot the CWP tone snag (tone does not cancel)

Repair remaining cockpit lighting.

Continue with spine harness repairs (airframe side) and refit harness.

Continue to try and reinstate electrical systems where possible (lights/avionics etc).

GROUND EQUIPMENT:

Get our GPU running and producing power.

Get our Hyd’s rig running.

ONGOING:

Stock check and document my current spares complement.

Try and source the following:

Centreline pylon

Additional 226OCU relevant ordnance

Continue to try and source missing parts as and when funds allow.

Getting the aircraft undercover or considering repaint probably still isn’t possible/practical at this point.

I won’t look to hang pylons until the aircraft is painted.

There will probably be another Open House in the summer if there is sufficient interest, I haven’t even begun to think about potential dates for this yet.

As always, many thanks for the ongoing interest and support.

OCTOBER/NOVEMBER ’22 UPDATE: Firstly, apologies for the lack of an October update. A combination of factors meant I didn’t get to sit down and catch up with the events of the month, such as there were, so I’ve rolled October and November into one bumper update here.

In early October a short break to the south coast meant there was an opportunity to visit the excellent Bournemouth Aviation Museum, the home of XX764’s sister aircraft, XX763.

The museum features a wide variety of aircraft and is open all year round, it’s well worth a visit.

Back at Enstone a couple of tasks have been crossed off the to-do list.

In the cockpit the main instrument panel have been replaced. The heads on the originals were badly worn so replacements have been sourced.

On the seat back bulkhead the ILS electrical connector has been replaced. The original was badly corroded having been submerged underwater for a long period of time at the aircraft’s previous home when the cockpit was not fully sealed.

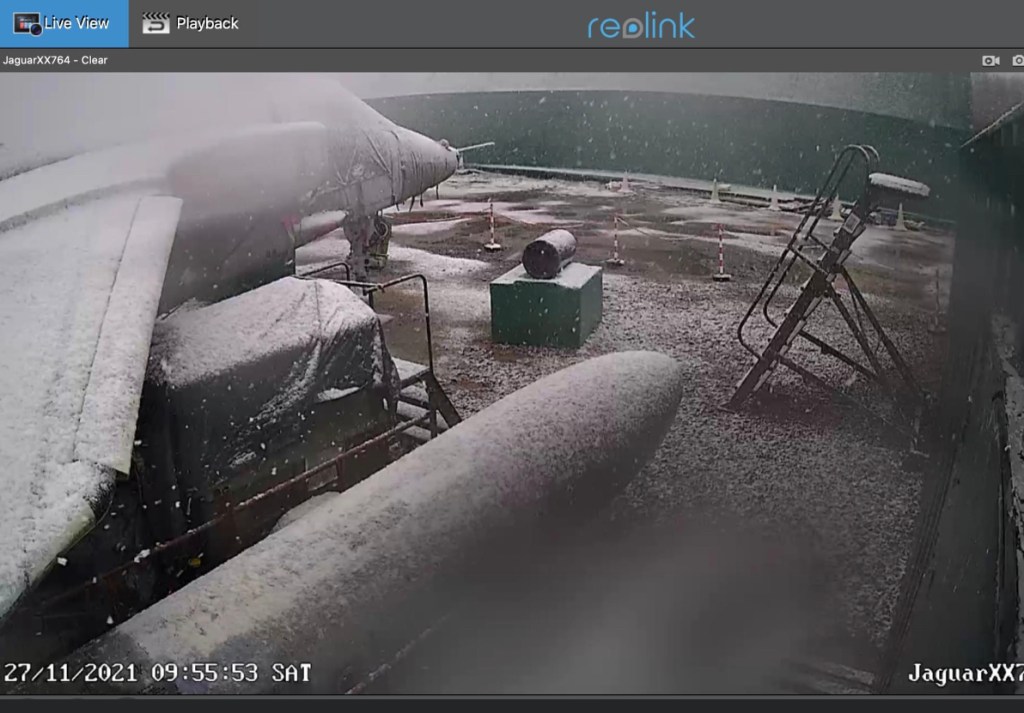

I’ve now closed up the cockpit for the winter to try and keep the worst of the weather out and everything as dry as possible. There are still plenty of tasks to complete externally without needing to open up the cockpit on a regular basis. The additional tarpaulin doubles up on the usual covers.

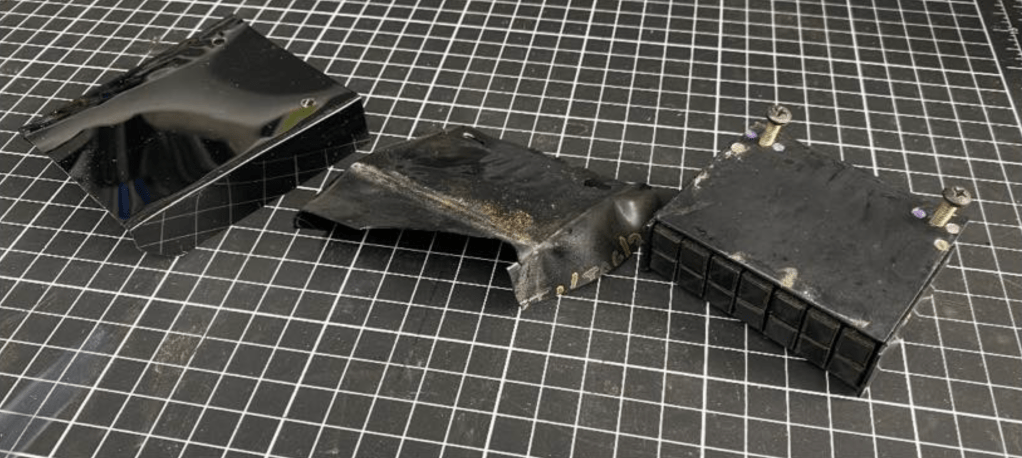

I finally got around to completing and installing the 3D printed Rudder Damper body and it’s associated hardware. The bracketry that attachs the damper to the rudder has proved as equally unavailable as the damper itself so I fabricated a set of parts. Without any pattern parts I had to make a few assumptions about dimensions but with the installation being halfway up the fin and only visible from ground level it has meant I didn’t need to make millimetre perfect replicas.

With the hardware ready it meant dropping the rudder back off it’s hinges to get the damper body in place and the brackets attached.

And comparing this to an original installation it doesn’t look too bad:

Now with the winter weather starting to make its mark focus will turn to a list of tasks on our ground equipment and infrastructure.

Inside the container our large scale Jaguar model has been suspended from the ceiling to get it up out of the way. It still needs some rework and repairs at some point as well as a repaint into XX764’s livery.

I’m still managing to source additional parts, October and November have seen the arrival of a ‘new'(not new) E3R Inertial Platform, a SNEB rocket pod nose section and a variety of airframe parts.

On the merchandise front there have been several new additions to our range. Everything we sell through our various outlets (website/Etsy/eBay) all contribute to directly assisting the aircraft in all areas.

We have been very lucky to receive assistance from renowned Dutch digital aviation artist Peter van Stigt. Peter has produced a number of renders for us featuring XX764 and the first of these is now available as a limited edition framed print which is already selling well.

Produced on gallery quality paper and supplied framed ‘Across The Loch’ can be found on the merchandise page.

Other new additions to the merchandise range include a metal Jaguar bottle openers, 2023 calendars, XX764 caps and our latest item, a full colour PVC patch of the XX764 fin produced for us by the team over at Runway25 (https://runway25.com). All items can be found over on the Merchandise page.

In the run up to Christmas there are a few postal strikes planned in the UK so please bare this in mind when planning your shopping!

And that about wraps up the events for the last couple of months. As always, many thanks for the ongoing interest and support.

Neil

SEPTEMBER ’22 UPDATE: Only a brief update this month unfortunately. I lost nearly a fortnight at the start of the month with work commitments that included a trip to Japan which conspired to limit my time with the aircraft.

Whilst I was abroad the most recent MoD Disposals Auction took place. Whilst most of the lots only held a limited interest for me, a couple of items of potentially useful Ground Support Equipment stood out on the auction list and I got back from my trip to find that my bid for an ex-RAF Hydraulic Rig had been successful.

With the unit collected and returned to Enstone, it needed a bit of a clean up and a couple of missing parts replaced but, when I eventually get the hydraulics system on the aircraft relatively complete (the engine side pumps will obviously never be fitted), I hope to be able to return a few systems to a limited degree of functionality.

Another batch of parts also arrived this month most of which are destined for the brake parachute installation as well as the spine air con, the spine mechanical attachments and a few other parts.

The final ‘new’ arrival at Enstone this month was a distinctly not-new Type Y Weapon Loader Trolley. I seem to have a knack for collecting parts that need a make-over before they become actually useful (!!). This will get some love over the winter.

As usual, the purchase of all these items this month have been hugely assisted by recent merchandise purchases and donations. Huge thanks if you’ve bought anything recently.

Finally, for this month’s news the mini Jaguar resin model kits arrived from Japan. These went on sale through my Facebook page and seemed to prove pretty popular, the first batch almost all now sold (I have just a couple of kits left if anyone is interested). One assembled and painted kit also arrived so I took the opportunity to take a couple of snaps of it with the aircraft.

And that about wraps up the events of September. As always, many thanks for the ongoing interest and support.

Neil

AUGUST ’22 UPDATE: The first task undertaken going into August was the refitting of the tailplanes, in order to have the aircraft in a cosmetically complete (as possible) state for the Open Day on the 13th.

The preparation work done in advance of this came into play and the refit of the tailplanes and C-Levers was as straightforwards as it’s possible for it to have been given it was pretty much just myself and my Dad involved (with thanks to the random visitor that got involved in lifting the second tailplane into place).

There may also have been a fair degree of swearing but I’m neither able to confirm nor deny this.

Although mechanically the rear end control system is now pretty complete I will need to revisit it at some point to continue the bay cleaning as well as refitting all the flexible hydraulic pipework and some split-pinning and wire locking where practical.

Obviously the tailplanes are not rigged, and I neither have the kit nor experience, nor particular requirement for them to be any more than complete and secure in a relatively representative position.

I still need to revisit the rudder installation in order to refit a PFCU and pipework etc. More on the rudder later in this update.

So with the aircraft relatively complete my focus then turned to getting the site ready to receive visitors for the Open Day. The UK’s Summer heat wave was in full effect but a few brave souls still ventured out and hopefully found the visit interesting. It was good to catch up with many ‘regulars’ but I do appreciate everyone’s interest and attendance on what was a very hot and long day. Please accept my apologies if you visited but I wasn’t able to have a chat in person.

Additionally, a big ‘Thank You’ to my Dad and to Rich Clarke for helping out on the day.

Thanks also to everyone that either bought merchandise on the day or have made a donation subsequently, it all really does help and hopefully you were able to see where your financial assistance is helping out in very practical terms.

Several people have subsequently got in touch who weren’t able to attend on the day asking about visiting XX764. Of course this is always possible but I’d ask if you are planning to visit to try and at least message me first, as, if the weather is good, I’ll open the cockpit etc so it will make for a more interesting visit.

After the dust had settled on the Open Day it has been a case of relocating several parts back to their regular storage locations and picking up back with some further aircraft tasks.

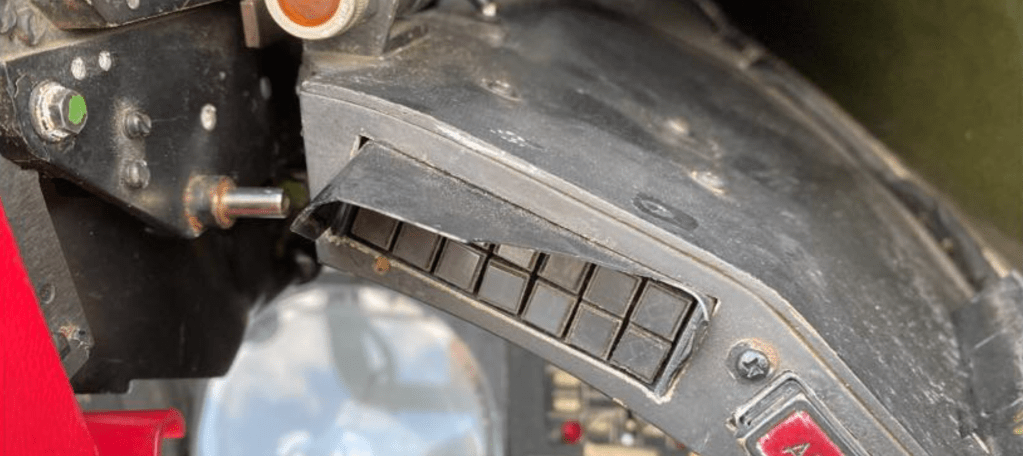

One long term resident on the missing parts list is, as I’ve mentioned before, the rudder damper assembly. Still a current part for the indian Air Force aircraft these really are unobtanium with pretty much every available unit having been snapped up by parts dealers or bought, overhauled and sold to India, but as a missing part is does leave a large void on the leading edge of the rudder.

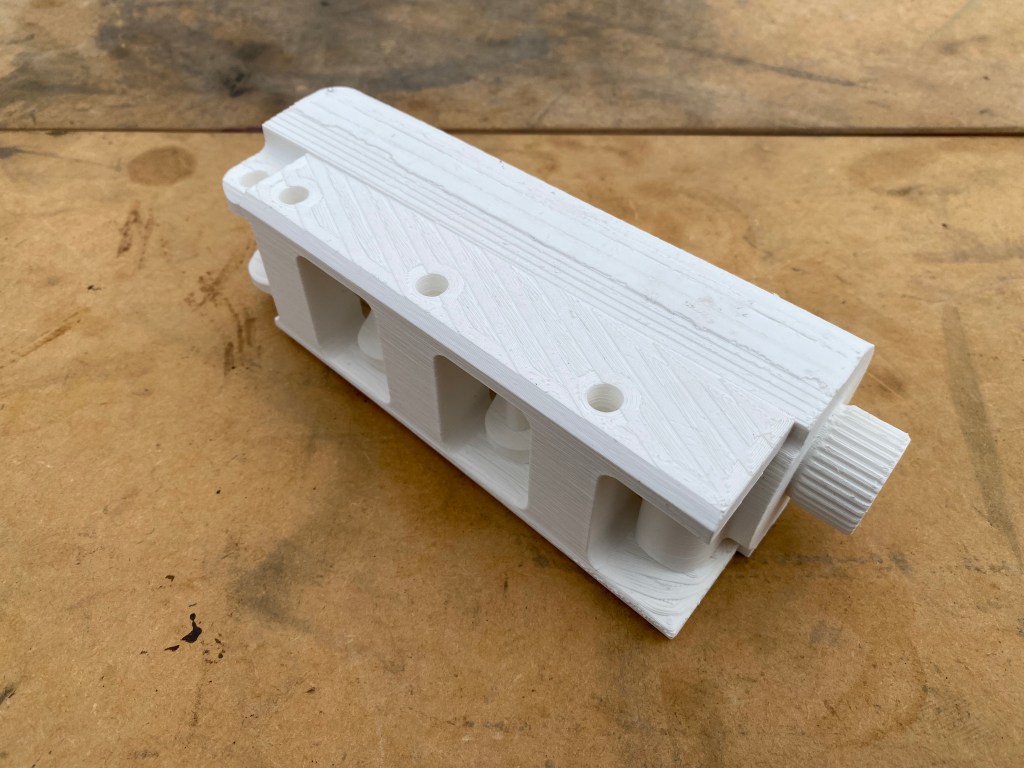

I had been in contact with the UK based overhaul agent for these parts and although they weren’t able to assist with a real part (and my budget doesn’t stretch to the approx. £30k required to buy one) they were able to produce a 3D printed replica piece which is a fantastic substitute.

The 3D print is basically the damper body and installation bracket as a combined piece. With a bit of finishing and a coat of paint it is pretty much ready to fit.

I still need to fabricate the linkages from the base of the ‘damper’ out to the port side and then the link aft to the rudder itself and will need to drop the rudder back off the hinges to actually fit the fake damper assembly but when it’s in place it should be pretty much indistinguishable from the real thing when viewed from the ground. Huge thanks got out to AEI Systems for their assistance with this project.

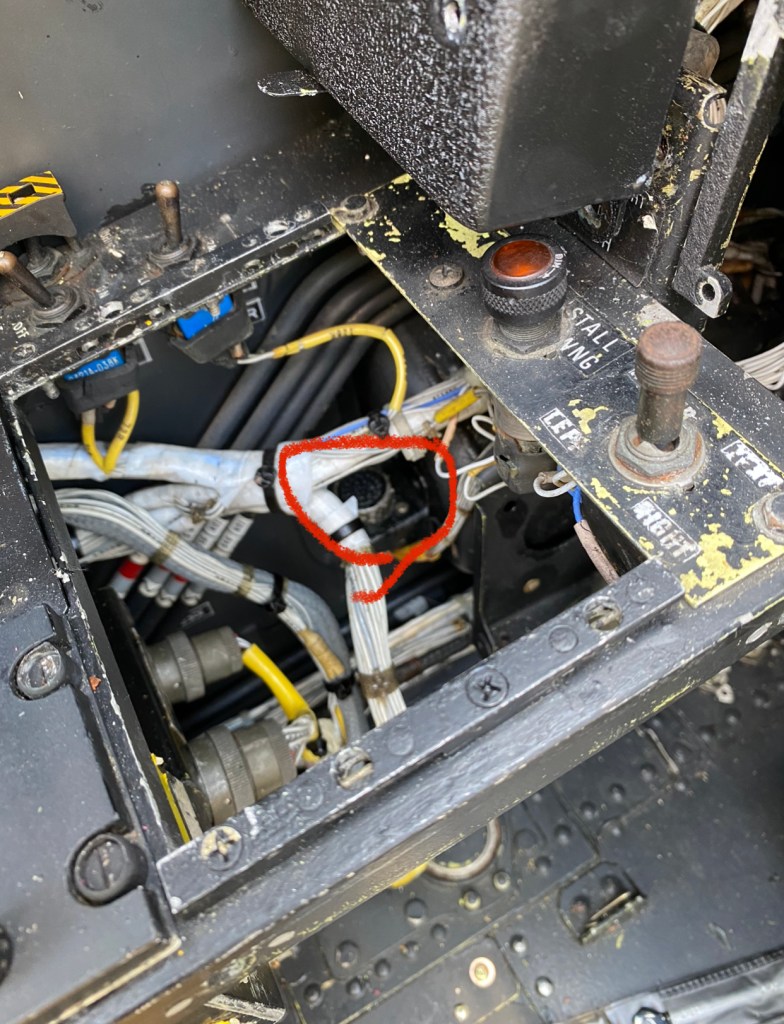

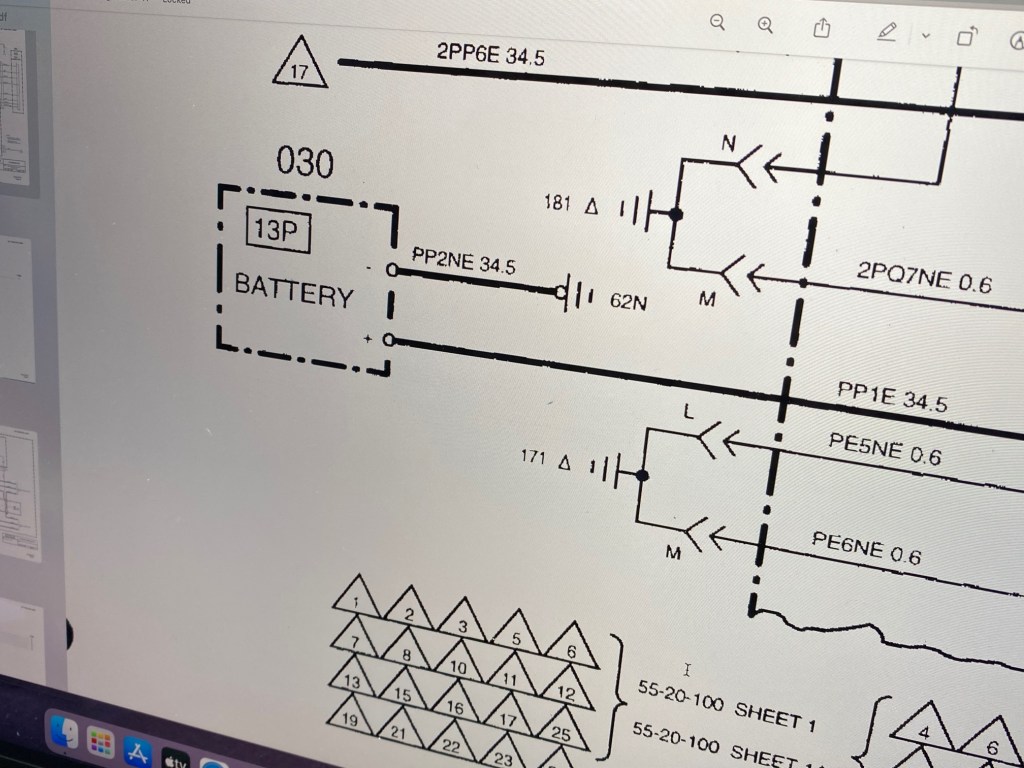

I’ve also been trying to fix a snag on the Master Caution installation where the audible warning doesn’t mute and Coaming flash doesn’t cancel.

My initial thought was that it would be an internal issue in the Master Warning Control Unit so I removed the coaming and replaced the unit with a spare (and also took the opportunity to replace the HUD EHT unit with a NOS unit in anticipation of hopefully some progress on the NAVWASS installation further down the line (this is probably VERY optimistic I realise!)).

Unfortunately this hasn’t proved to be a quick fix so will remain on the to-do list for a while longer as I work my way through the wiring manuals (or it is possibly ‘just’ two duff boxes).

That about wraps up the events of August. As always, many thanks for the ongoing interest and support.

Neil

JULY ’22 UPDATE: Well, following on from limited progress in June, July saw a similar picture unfortunately. The first week of the month I was in Italy with work and then this was pretty much followed up directly with a week at the returning Royal International Air Tattoo after it’s two-year covid-induced hiatus.

Whilst at RIAT I was lucky enough to come across this Wilf Hardy artist’s proof print of some fairly Jaguar-related artwork that was used as the cover of the RAF Yearbook in 1991.

Back at Enstone and work has continued rebuilding all the missing hardware in the rear end of the fuselage, primarily the tailplane mechanical control system.

The missing PFCU’s have been sourced and refitted, as has the remaining mechanical linkages and feedback sensors in readiness for the tailplanes themselves to be refitted.

On the tailplanes themselves I’ve taken the opportunity while they were removed to tidy up some damage in various areas.

The inboard leading edge of the port tailplane had, at some time in the past, taken a pretty heavy knock. The metal was beyond simply back into place so I took the fairly dramatic route of cutting out the damage completely and fabricating a small replacement piece and then blending it back into the original skin. Sheet metalwork isn’t really my thing but it has worked out OK.

The inboard trailing edge corner of the same tailplane was also in a pretty poor state so this was also removed and a replacement section grafted in to place.

The plan is to now refit the tailplanes prior to the forthcoming Open House Day to have the aircraft in a pretty cosmetically complete state. The tailplanes, although fitted, won’t be rigged – I have neither the kit nor experience or requirement for them to be any more than just fitted to the aircraft.

And finally, I am now preparing the aircraft and site for this coming weekend’s Open Day (on the 13th). Thanks to everyone that has already pre-registered, emails will go out later this week with details of the day and directions on how to find us.

If you would like to come but have not yet registered it would be hugely if you could pre-register using the Eventbrite link here: https://www.eventbrite.co.uk/e/326715955217

This will make it easier for us logistically as the Flying Club also have an event running and we can better assess parking, catering requirements etc.

I hope to be able to catch up with a few of you at the weekend (the good weather looks set to stay).

As always, many thanks for the ongoing interest and support.

Neil

JUNE ’22 UPDATE: June has unfortunately been a month of limited progress with XX764. This has been down to my being out of the UK for the first two weeks of the month with work (got to pay for those new parts somehow), but even so, we’ve made some headway in a couple of areas.

Our container workshop/store at Enstone has had a fresh coat of Olive Drab and is looking very smart (thanks to my Dad for labouring away at this).

This month we were contacted by one of our social media followers who had some original Jaguar training posters gathering dust at home and who was kind enough to donate them to us. These have been framed and now mounted in the workshop space at Enstone.

Work has continued at the rear end of the aircraft. The aft most bay that would normally house the Rudder PFCU (long since removed by the aircraft’s previous owners) and brake parachute canister, has had a good clean up in preparation for reinstalling the missing mechanical parts.

I have pretty much all the parts to fully restore this area to completeness.

I have also spent a fair amount of time in making good some of the skin damage inflicted on the aircraft by some pretty crude bracketry that had been fitted to hold the tailplanes in a fairly representative position (with all the internal parts having been removed they would have just drooped into the vertical otherwise)

And the brand new pair of tailplane C-Levers have been pre-fitted to the tailplanes prior to their being reinstalled.

The final task achieved this month was the fitting of missing hardware to the rudder hinge points with the rudder being now ‘properly’ attached. I’m still completely missing a Rudder Damper but don’t really anticipate being able to find one of these – it’s been a long term resident on my Missing Parts spreadsheet. The rudder itself was initially pretty stubbornly seized in the lower bearing but this has gradually been freed off and now pivots as it should.

Many thanks to those that have already pre-registered for this summer’s Open House day on Saturday August the 13th. The day itself is free to attend, but it would be hugely appreciated if you are planning to come that you pre-register using the Eventbrite link here: https://www.eventbrite.co.uk/e/326715955217

This will make it easier for us logistically as the Flying Club also have an event running and we can better assess parking, catering requirements etc.

And finally, with the Royal International Air Tattoo on the verge of returning in July after a two year Covid enforced break, here’s an archive image of XX764 on the flight line of the 1979 International Air Tattoo, held in those days at Greenham Common.

As always, many thanks for the ongoing interest and support.

Neil

MAY ’22 UPDATE: May has seen some solid progress across a number of areas on the aircraft. As the summer progresses I aim to get a few of the the bigger tasks ticked off the to-do list whilst taking advantage of the better weather.

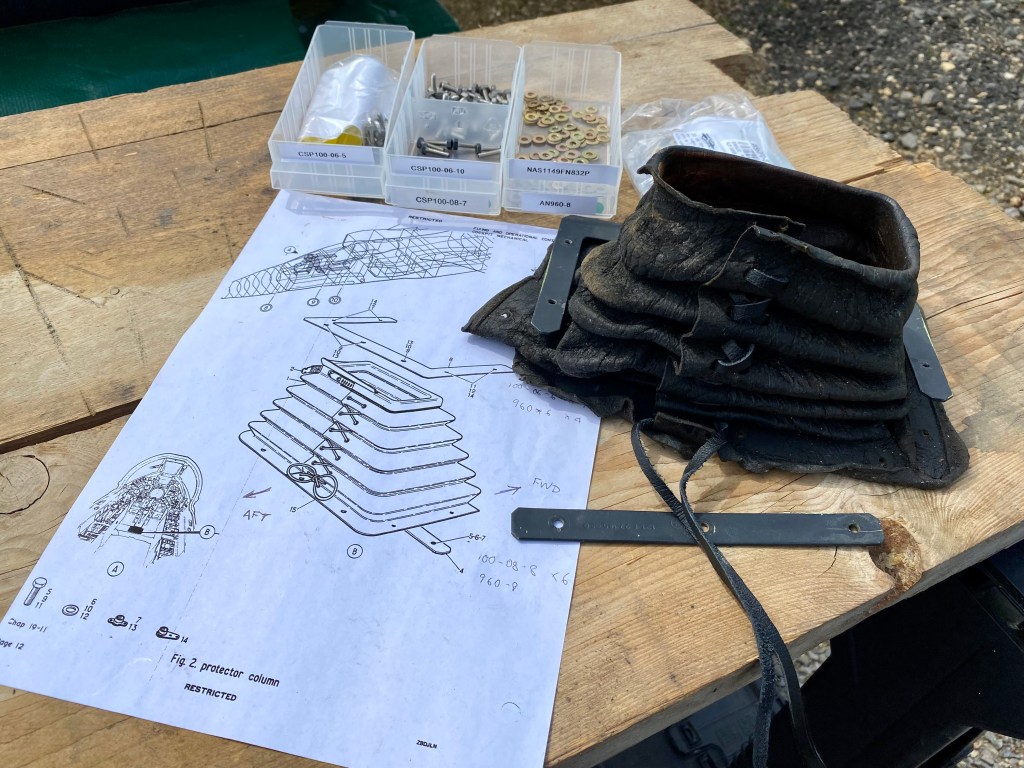

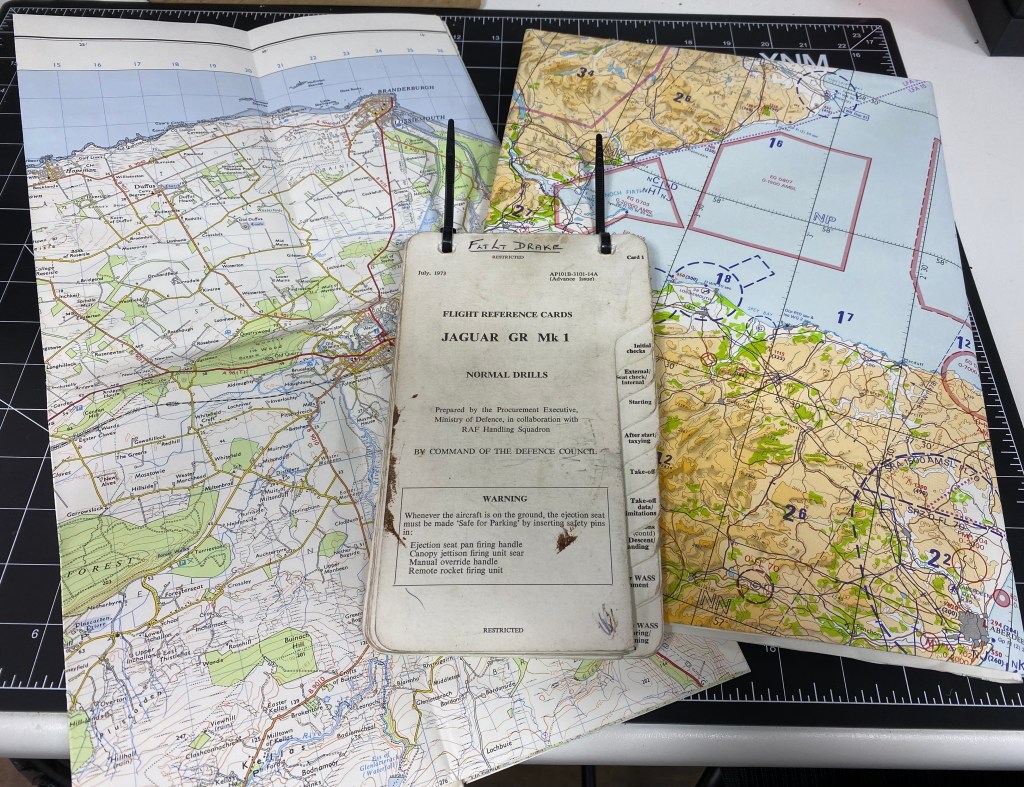

Following on from the work achieved in April a few more cockpit jobs have been completed. The HUD Pilot Data Recorder, sourced at the Newark Aeroboot sale, has been fitted, the Control Column gaiter refitted and the console side trims, removed for access to the Flaps/Slat/Undercarriage indicator connector have also all been fitted.

I have also bought set of period RAF Low Fly charts and OS Map to be able to ‘kit’ the cockpit as well as a set of donated original GR.1 Flight Reference Cards.

In the aft equipment bays, under the fin, cleaning work has started prior to fitting as much as I can of the missing tailplane and rudder hydraulics and controls, which had all been removed by the aircraft’s previous owners.

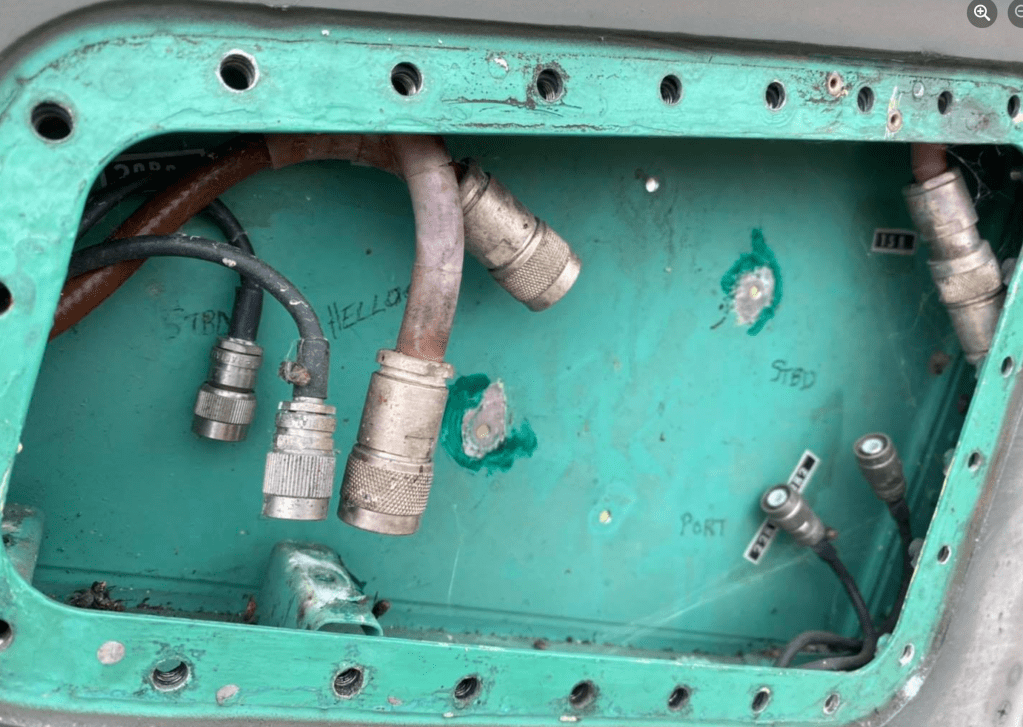

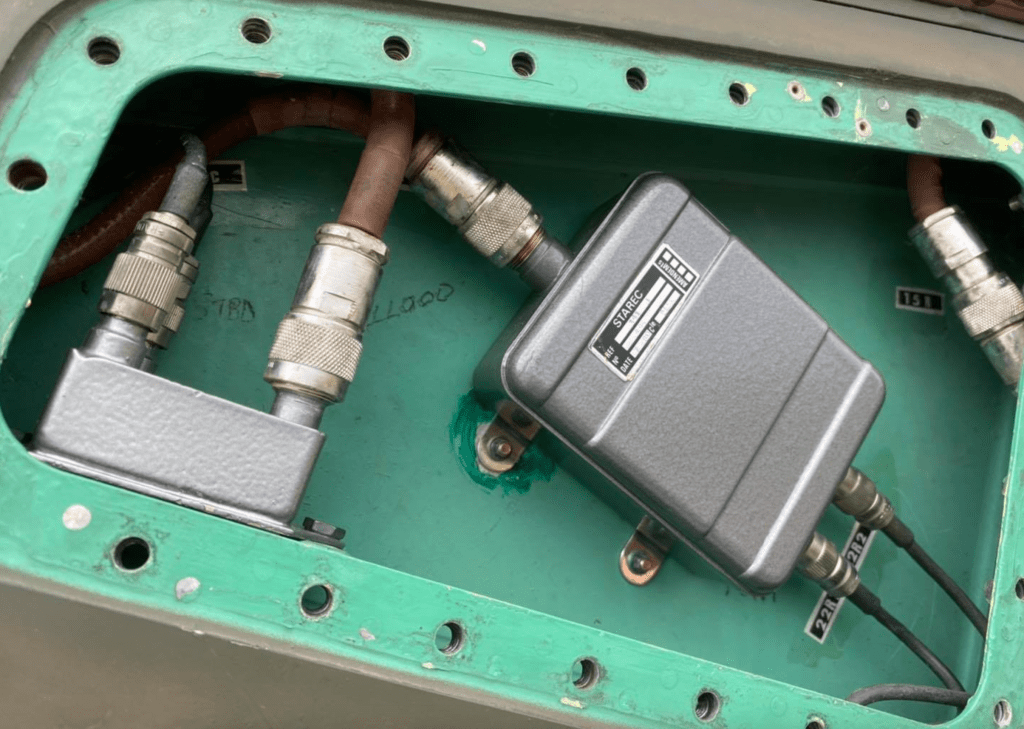

In the port inboard equipment bay the missing fuel tank pipework and some of the aerial splitter hardware has also been fitted, as well as the bay getting a general tidy up.

I continue to locate ‘new’ parts for the aircraft. This month also saw a visit to the excellent annual Boscombe Down Aviation Collection’s Aerobilia sale, where a few more items were sourced.

Finding new parts is always assisted by the sale of my small merchandise range and this month I’m pleased to be able to launch a new item to the range. These beanie hats, available in Black or Green and featuring the XX764 logo embroidered on the front are now on sale here on the website’s ‘Merchandise’ page as well as our Etsy and ebay seller accounts.

This month also saw an addition to the fleet in the form of this large scale Jaguar model, found through eBay. I suspect it was probably produced for use in a Recruiting Office. It needs a little bit of TLC in a few areas and the aim is to have it in XX764’s original 226OCU colours and camo paint scheme.

Back to aircraft tasks and another area that had been stripped of all saleable parts previously was the fwd spine air conditioning and comms aerial hardware. I’ve been accumulating parts for a while to rebuild this section so it was quite satisfying to be able to see everything come together and another area relatively complete.

Finally, many thanks to those that have already pre-registered for this summer’s Open House day on Saturday August the 13th. Free to attend, it would be hugely appreciated if you are planning to come that you pre-register using the Eventbrite link here: https://www.eventbrite.co.uk/e/326715955217

This will make it easier for us logistically as the Flying Club also have an event running and we can better assess parking, catering etc.

As always, many thanks for the ongoing interest and support.

Neil

APRIL ’22 UPDATE: With the weather here in the UK gradually improving, it becomes less of an arduous task to start making some progress again on the airframe. Over the winter airfields tend to be pretty bleak places!

April has seen advances in several areas as we start to make plans around some of the aims for this summer’s workload.

I’ve revisited some unfinished tasks in the cockpit, one of which was to locate the airframe side connector for the Landing gear/Flaps/Slats Indicator, which I’d previously been unable to find. As it turns out it was almost adjacent to the indicator but buried away on the outboard side of the LH instrument panel and some minor dismantling to gain proper access to the connector had to be done.

With the unit finally plugged in though, a few blown filaments required replacing, which has been done (fiddley little buggers) and the coaming panel has been refitted.

This just leaves the LH console side panels to refit.

With the coaming back in it was an opportunity to re-assess where I am at with the cockpit lighting. The aircraft is currently still only being powered from DC battery/static inverter so there are a couple of elements that I can’t yet power and I know I have a few issues to sort but the instrument panels are starting to come alive again…

Whilst spending some time focussing on the cockpit it has also been an opportunity to finally change out the pistol grip stick top that I have had on the spares shelf for a while.

External to the cockpit and back in the starboard wing root equipment bay, the missing slat limit switch has now been fitted. I still need to fit some O-Rings to a few of the fuel unions and sort out bonding leads and wire locking but in terms of missing parts this area is just about now complete.

This ‘just’ leaves the port side bay to sort to a similar level….it’s on a ‘to-do’ list..

One major ‘win’ this month was to finally locate a long term piece from one of my many missing parts lists. An incidence probe, fitted on the forward port side of the nose, has been located and fitted, another hole finally filled.

And right at the tail end of the month I was lucky to come across this Pilot Display Recorder unit at an Aeroboot sale at Newark Air Museum (a museum well worth a visit by the way). This unit fits on the front face of the pilot’s HUD and has been another long term resident on the cockpit missing parts list. It will be fitted when I’m next working in the cockpit.

And finally for this month, I’m please to be able to announce that I have a date for this summer’s Open House day, Saturday August the 13th. Although free to attend it would be hugely appreciated if you plan to come that you pre-register using the Eventbrite link here: https://www.eventbrite.co.uk/e/326715955217

This will make it easier for us logistically as the Flying Club also have an event running and we can better assess parking, catering etc.

I plan to obviously have the cockpit open but will also (if there is interest) be opening up many of the panels and equipment bays should any modellers want together some super-detailling information (or former crew just want to reacquaint themselves with a few of the Jag’s hidden treasures!)

Good weather has been pre-booked so I hope to be able to meet a few of you on the day.

As always, many thanks for the ongoing interest and support.

Neil

MARCH ’22 UPDATE: Only limited opportunities to crack into some tasks with the aircraft this month, real life has kicked in and I’ve spent a couple of weeks out of the country with work. That said, we’ve managed to make some progress in a couple of areas. I’ve taken the secondary cover off the canopy and was pleased to find that the cockpit has remained dry over the winter. Opening up the canopy for the first time in a few months was an opportunity to try out the new canopy seal protectors.   In the forward avionics bay the final missing component has been located. The airspeed switch, tucked away in the upper reaches of the bay, has been fitted complete with it’s associated pipework.    Cosmetically at least, this means that both avionics bays are now complete. As I start to get systems powered up there might be a bit of component swapping, spares allowing, but considering the starting point we’re not in a bad place.    With the electrical systems starting to come together I’ve started to revisit the missing and incomplete hydraulics pipework and fuselage-to-wing flying controls hardware.  In the fuselage equipment bays at the leading edge of the wing I’ve started to rebuild the missing pipework and have a look at some of the repairs required. Most of the hardware that is missing I’m able to replace from the stocks of parts that I’ve compiled but everything is getting a spruce up prior to installation.   The starboard bay is now more complete but I’ve pulled the slats limit switch unit as the electrical connectors are heavily corroded (beyond recovery) so the unit will be replaced with one from spares.   Fuel tank transfer and pressurisation couplings have also been sourced and fitted on the wing leading edge.   Apologies again for the briefness of the update this month. Hopefully April will prove more productive. I’m still sourcing parts and thanks go out to everyone that continues to support us by buying merchandise or direct donations. I’m intending to hold at least one Open House day over the course of the summer and will try to tie down some potential dates and these will be well publicised ahead of time. If anyone would like to ‘pop in’ to Enstone for a look around privately please drop me a message and I can try to be on-site to open up the aircraft, weather permitting. As always, many thanks for the ongoing interest and support. Neil |

FEBRUARY ’22 UPDATE: Back to our normal monthly update format after our 2021 overview. February has been, by UK standards, pretty stormy, with a couple of damaging storms ripping across the country. I was pleased to find no damage to XX764 after both storms and everything on-site remained intact, but with the weather proving unkind, progress this month has still been somewhat limited.

I’ve been continuing with the ongoing repairs to the spine harness and the end of this task is almost in sight (with ‘just’ the airframe side wiring to sort out when the weather improves).

I managed to locate a ‘real’ Laser Electronics Unit and replaced out the ballast unit that I’d fitted previously in the bay.

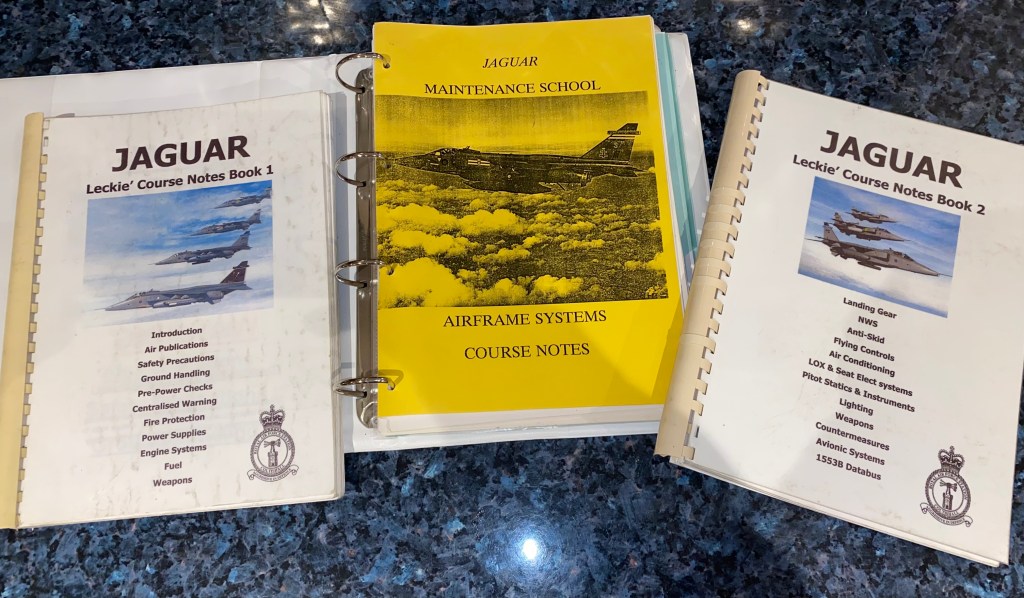

Someone got in touch via our Facebook page and donated these training notes, hugely appreciated.

The damaged tail section on one of our droptanks has been replaced.

Replacing this tail section will leave me with a section that is surplus to requirements.

The ongoing hunt and sourcing of parts continues. Some of the interesting parts found this month includes some specialist tooling for installing the pylons and tailplanes and these cockpit rim protectors.

Finally, for this month, I’ve fitted our Mk117 Retarded Tail to one of our 1000lb Practice Bombs, a nice little workout….Both elements obviously require repainting at some point.

Apologies for the briefness of the update this month. March is busy for me in the ‘real’ work world but hopefully by the time I get back to the aircraft the weather will really start to improve and progress can get back up to speed. Just another one of the downsides of an aircraft based outside 24/7….

As always, many thanks for the ongoing interest and support.

Neil

2021 UPDATE: Firstly, a belated Happy New Year! I hope everyone has had a safe and healthy Christmas and New Year break. Rather than just a conventional monthly update for December and January, I thought I’d use this update as an end-of-year report with an overview of some of the highlights of the past twelve months, as well as looking forwards to 2022 and some of the aims I have for the coming year.

2021 Highlights:

Engine start panel – During lockdown the engine start panel was rewired back from GR.3 to GR.1 spec

Nosewheel bay air conditioning installation – All the missing components of the cockpit air conditioning installation in the nosewheel bay were finally assembled and refitted.

Refuelling installation – I managed to track down an in-flight refuelling set of parts (all of which were missing originally) and refitted.

Nose leg refurbishment – The heavily corroded noseleg was finally refurbed back to a presentable condition.

Heatshield Bolts – All the heavily corroded bolts securing the aft keel heat shield sections were replaced (quite an investment!!)

Spine Harness wiring – The cut wiring at the forward area of the spine has all been terminated into mil-spec connectors in preparation for eventually refitting the full spine harness.

DC (Battery) Power – With the spine wiring all terminated and made electrically safe, the nosewheel bay AC and DC Junction Boxes were finally checked over before applying battery power to the aircraft. I have also powered up the standby (static) inverter for essential AC.

Ground Intercom – With power back on the aircraft I’ve made up an adaptor cable to be able to plug into the pilot’s comms wiring without the seat being fitted and tested the ground intercom socket with a pair of headsets.

Laser – The LRMTS (Laser Range and Marked Target Seeker) head has been fitted.

Paintwork – Some time has been spent trying to stabilise and, to an extent, restore the paintwork on the airframe. I know that the long term solution is a full repaint but with the aircraft outside 24/7 and it being a strong financial investment, currently it’s about hanging on to what I’ve got. It’s been ‘relatively’ successful (the green has come up better than the grey which is pretty poor still) but will always be a battle. Additionally the 226OCU markings, which had been painted over, have been revealed.

Avionics Bays – The final missing component (an Air Data Computer) has been located and fitted. Both bays now have a complete complement of units installed but as to their serviceability, this has yet to be established (most don’t need to work to be honest).

Open House Event – Back in August we were able to hold an Open House day which seemed to go down quite well with all that attended. It was also great to meet a few people that have been following progress for a while and have a connection with the aircraft at various stages of it’s history. I’ll definitely look to make this an ongoing annual event.

On-site Storage/Workshop space – At the tail end of the year we had the opportunity to expand our storage and workshop capacity at Enstone. This will prove invaluable in terms of consolidating and cataloguing our spare parts.

Merchandise and Donations – Away from the aircraft, we were pleased to team up with the team at Flyingraphics to design our own tee-shirt design which went on sale during the year to expand out small merchandise range. It seems to have been well received so thanks to those that have already ordered one as well as all the other merchandise items bought throughout the year.

Finally, a huge thank you to those that have made donations this year.

Plans for 2022:

Ground Power Generator – With the aircraft now able to be powered up, getting our 25kVA Ground Power Unit serviceable becomes more important as it will allow me to start getting some of the electrical and avionics systems hopefully back on-line where possible.

Spine – As well as continuing with the restoration of the spine wiring, which is on-going, I’ll also be looking to rebuild the pipework and control runs that are all currently missing.

Tailplane and Rudder Hydraulic installation – The whole rear end control systems have been previously removed and are currently missing. I have been accumulating parts and will be looking to rebuild the hydraulic actuator/control pipework systems.

Cockpit – As I gradually reintroduce power to various systems there will be plenty of troubleshooting to undertake, I don’t anticipate too many parts working and to be honest most don’t need to, but Im keen to get as much working as I possibly can.

I’m sure more tasks will present themselves over the course of the year but these are a starting point. As usual I’ll always be constantly adding to my parts stock – every panel that gets removed seems to have something missing behind it so I am continually updating my missing parts lists.

So that’s about it as an overview of 2021 and a clue of what 2022 hopefully holds. I’ll aim to hold an Open House in the Summer but this will be planned as we get further into the year. As always there will be plenty of updates through our usual social media channels and if anyone needs/wants to get in touch just ping me a message.

As always, many thanks for the ongoing interest and support.

Neil

NOVEMBER 2021 UPDATE: Winter has really started to make it’s presence felt in the UK this month, hopefully everyone is doing OK and hasn’t been too badly affected by the recent bout of bad weather.

Following on from last month and the expansion of our storage and workshop capacity at Enstone this month has again been predominantly spent sorting out our infrastructure and spares.

Our ‘new’ seat servicing stand is now fulfilling it’s role with our seat loaded. We’ve still got a long shortage list for quite a few parts for the seat and along with plenty of other areas, it’s still work in progress but there’s no rush to get this complete.

On the aircraft I’ve sourced a pair of surplus Ground Intercom headsets through our old friend eBay. I’ve also made an adaptor cable to be able to plug into the comms connector that would normally attach to the seat and an extension cable for the external intercom socket. This has all now been tested and is working fine so will be useful when it come to safely powering up and testing various cockpit controlled systems later in the restoration.

In the cockpit the Attitude Indicator (Artificial Horizon) has been replaced for a spare as the unit I’d originally fitted popped the circuit breaker as soon as power was applied. Such is the nature of sourcing parts of unknown serviceability from places like eBay – it’s one thing to fill a hole but another to find something that has a limited level of functionality (the odd shiny bolt will be touched in with a spot of black paint at some point!)

Prior to replacing the Attitude Indicator the coaming panel was removed as I’ve got plenty to do behind the instrument panels in the Spring. A final view of the cockpit before sealing it up to keep the worst of the Winter weather out…

A cockpit has now been tape sealed and double covered with an additional tarpaulin.

I was lucky enough to come across this original Jaguar outboard pylon, complete with attachment hardware and ERU still installed.

Outboard pylon.

Additionally we’ve found these New/Old Stock Static port blanks.

Finally a quick image from our security camera of some of the winter weather that’s getting us in the Festive spirit at Enstone.

Thanks to everyone that has ordered items from our merchandise range (details under the ‘Merchandise’ link at the top of the page). With Christmas now just around the corner we’re ready to supply all your Jaguar XX764 gifting needs and all proceeds roll directly back into assisting the aircraft.

As always, many thanks for the ongoing interest and support.

Neil

OCTOBER 2021 UPDATE: A somewhat more curtailed update this month after September’s progress in getting power back on the aircraft..

This month has, in the most part been concentrated on expanding and enhancing our storage and workshop capacity at Enstone. As those that have visited us in the past will know, we were previously renting half of the 40′ ISO container located next to the aircraft. The remainder of the container became available in October so we have taken on the additional space and spent some time in getting it organised into an effective parts store and workshop space.

We have also added a couple of additional items of ground support equipment this month.

An Ejection Seat servicing stand will help make the seat much easier to move around whilst it remains out of the aircraft and am still hunting for parts to complete it.

We’ve also adapted a small trolley to accept an external battery to provide 24VDC whilst we are starting to power up various airframe systems. This will save refitting and removing our donated Jaguar battery.

In terms of tasks on the aircraft this month the news is more limited. I have sourced and fitted an RF Distribution Box in the TACAN unit bay (I still need to locate a TACAN unit!).

And that’s about it for October’s news. As we start to get deeper into the winter I’ll soon be looking to get the cockpit fully wrapped up for the worst of the weather. I’ve still got plenty of other areas to concentrate over the next few months and now with power back on the aircraft I need to keep the cockpit as dry as possible.

Christmas is fast approaching and our merchandise page is still ready to supply all your Jaguar XX764 gifting needs with all proceeds roll directly back into assisting the aircraft.

Thanks, as always, for the ongoing interest and support.

Neil

SEPTEMBER 2021 UPDATE: True to form September’s update appears well into October, sorry about that.

This month has seen some solid progress in several areas on the aircraft.

As we start to prepare for the winter and the less favourable time of year for outdoor tasks there are still a few tasks that I’d like to get ticked off the to-do list before I seal up the cockpit for the duration.

At the start of the month a second seat was located which had a couple of items that were missing from our seat. The harness retraction unit was removed and fitted to our seat, quite an involved job that meant stripping both seats substantially.

One of the major aims for this year has been to restore electrical power to the aircraft. Although the AC and DC distribution boxes in the nosewheel bays have been complete for a while now and all the control units located and fitted, the major area holding me back has been the wiring damage at the front of the spine. This all needed to be made electrically safe and prepared for eventually reinstalling the repaired spine harness (which is still work in progress). With a large amount of wiring to be sorted I initially started with this pair of co-ax aerial cables:

The cut wiring was all separated into distinct bundles and terminated into mil-spec connectors. These connectors will be mirrored on the harness that will eventually be refitted to the spine and will mean that should the wing need to be removed in the future it will become a far simpler task (and not need to be cut!).

With this wiring all terminated into connectors I then set about powering up the aircraft for probably the first time in roughly 20 years. This has been done initially (and tentatively) with an external 24V Battery. All the cockpit circuit breakers were tripped and isolated as I wanted to power systems up in a controlled manner. There are only a few essential systems powered on the battery bus-bar.

With DC power safely online I then reconnected the static inverter to power the Essential AC bus-bar.

There is still plenty to do and plenty to check but I’m quite pleased to get past this initial hurdle, especially when this was our starting point in the cockpit all those years ago….

As well as the restoration of limited power to the aircraft a few more tasks have also been ticked off.

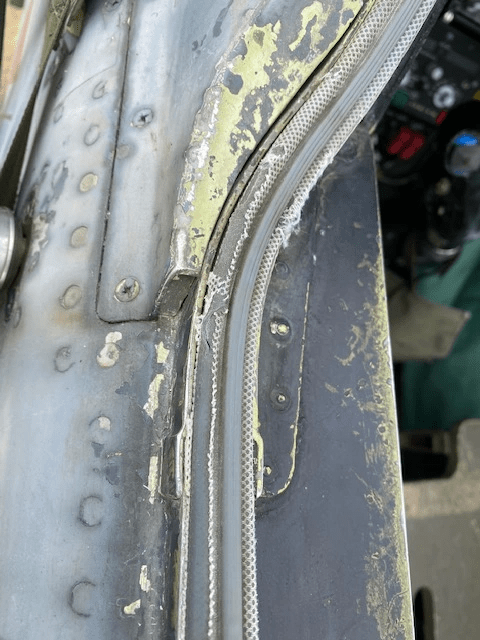

A replacement canopy seal has been located and fitted:

And in the fin the missing compass flux valve installation has been replaced. A new flux valve has been fitted, all the missing bracketry has been sourced and a new electrical loom made and fitted.

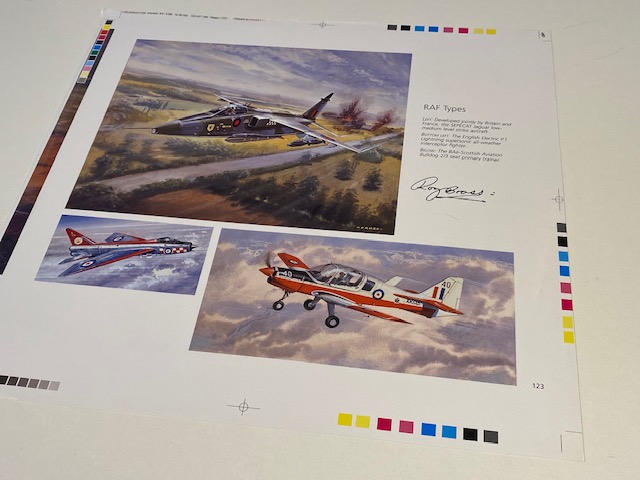

It was also nice to find this piece of Jaguar related memorabilia this month. An original printer’s proof sheet of iconic Airfix model kit box art that has been signed by artist Roy Cross.

That about wraps up September’s news.

Don’t forget that with Christmas (yes, I did say Christmas) approaching that our merchandise page is still ready to supply all your Jaguar XX764 needs and all proceeds roll directly back into assisting the aircraft.

Thanks, as always, for the ongoing interest and support.

Neil

AUGUST 2021 UPDATE: Slightly more on time this month!

Although I’ve lost a couple of weeks this month due to work commitments in France, there are still a couple of areas that we’ve made some progress in and of course early in the month we held our Open House day.

We finally were able to welcome a few visitors to Enstone for our 2021 Open House. Many thanks to those that took the time to pre-register and then brave a fairly poor weather forecast for what turned out to be a fairly average British Summer Day.

Hopefully everyone that came found it interesting and huge thanks to those that made donations and bought some of our merchandise.

If you came and I didn’t get a chance to have a chat over the course of the day, apologies.

Subsequent to the Open Day a few more tasks on the aircraft have been ticked off the ‘to do’ lists. The throttle rods have been reconnected in the left hand console (after the seized throttles were removed to free them off) and the repainted side panels have been refitted.

In the fin the missing ILS aerial baluns have been sourced and fitted.

And in the cockpit the damaged glare shield on the PWR Repeater panel has been removed and a new one has been fabricated.

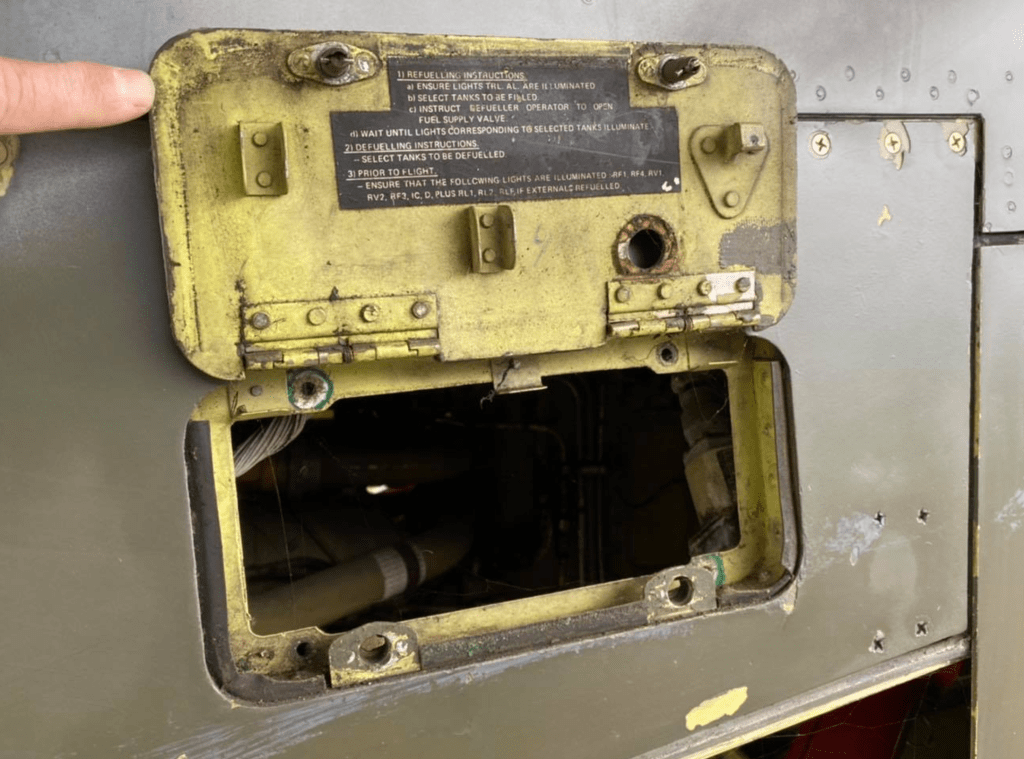

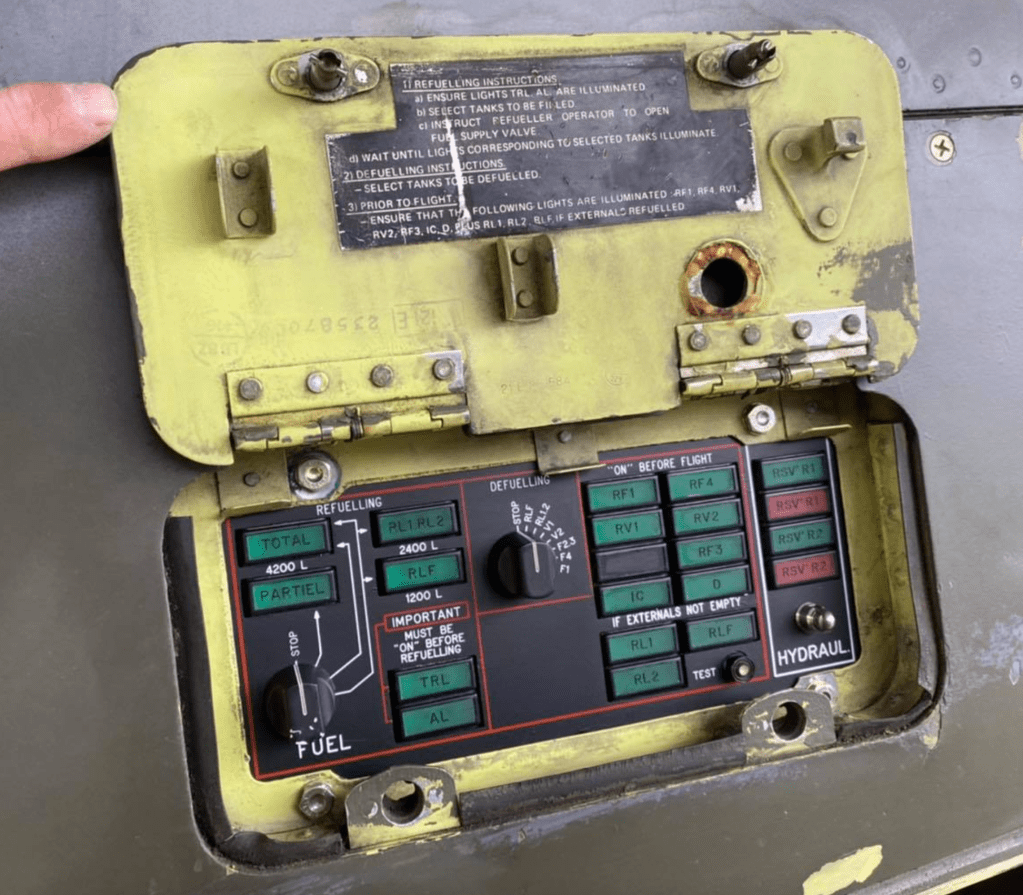

On the starboard side the missing Refuel Panel has been refitted having been tested prior on the bench to make sure all the annunciators illuminate (not that I anticipate actually really using it).

And finally, our tall set of steps have received some love – and an additional coat of paint.

Thanks, as always, for the ongoing interest and support.

Neil

JULY 2021 UPDATE: Hmmm, well having been a bit tardy in getting the site updated for June going into July, I’m in exactly the same boat for July into August. Apologies for that.

In terms of progress on the aircraft this month most of the focus has been in catching up with fitting a few items ahead of the Open House day (last weekend – a full update on that in August’s end of month round up).

I’ve finally got round to completing the nosing refurb (the first image gives an idea of the starting point). The clips securing the wiring on the starboard side and pipework on the port were fitted after the photos were taken. The new paintwork still looks a bit fresh but I’m sure it will tone down with a bit of weathering. It’s been a bit of a long slog but it’s nice to get this now looking fairly tidy. There is still plenty to do in the nosewheel bay but getting the leg finished and the door refitted is a decent start.

Having sourced the final missing unit for the starboard console in the cockpit it was just a case of giving it all a final eyeball over and hoover out before fitting the repainted side panels.

Having worked my way around (and spending a small fortune) replacing the heat shield bolts I turned my attention to getting the arrestor hook refitted. There was the not-so-small task of overcoming the powerful extension spring which, with the hook removed, was locked at 90 degrees to the airframe. A copious amount of swearing as well as a decent level of brute force seemed to do the trick but to err on the safe side the hook is not under it’s in-service spring tension. I do have the proper ground lock pin somewhere but can’t put my hand on it immediately so a temporary bolt was initially fitted to hold the hook in place. The access hatches to the lower bolts for the tailplane PFCU’s are removed as the tail area is still on the to-do list.

And finally this month I refitted the Laser Ranger and Marked Target Seeker (LRMTS) head unit in the nose chisel. I’d sourced this unit a fair while ago now but wanted to get the air conditioning system around the laser installed as well, the cooling fans and door actuators had all long since gone but this area is all complete now.

As mentioned earlier last weekend (7th Aug) saw our 2021 Open House. I’ll do a proper write-up on this for the end of August update.

Thanks, as always, for the ongoing interest and support.

Neil

JUNE 2021 UPDATE: Well, firstly apologies that this update comes a few days late as we are now well into July, I’ll try and be more prompt going forwards.

June has seen progress in several areas, some of which I am focussing on ahead of our Open House which is still on course for August the 7th. More details on that further down the page.

One avionics unit I don’t really anticipate being able to locate is the Laser Electronics Unit that would have lived in the lower access panel under the main avionics bays, so when this original dummy ballast unit became available it was the perfect opportunity to fill the aperture with the next best alternative.

It’s always nice to stumble on some hidden treasure and these messages written on the inner face of the Ajax cover panel were a bonus find when cleaning the panel. If you can’t quite make it out it reads “From Abingdon with all our love – Back to you with laughter”

I’m continuing to make progress revealing the painted-over 226OCU squadron emblems on the intakes, this is the port side.

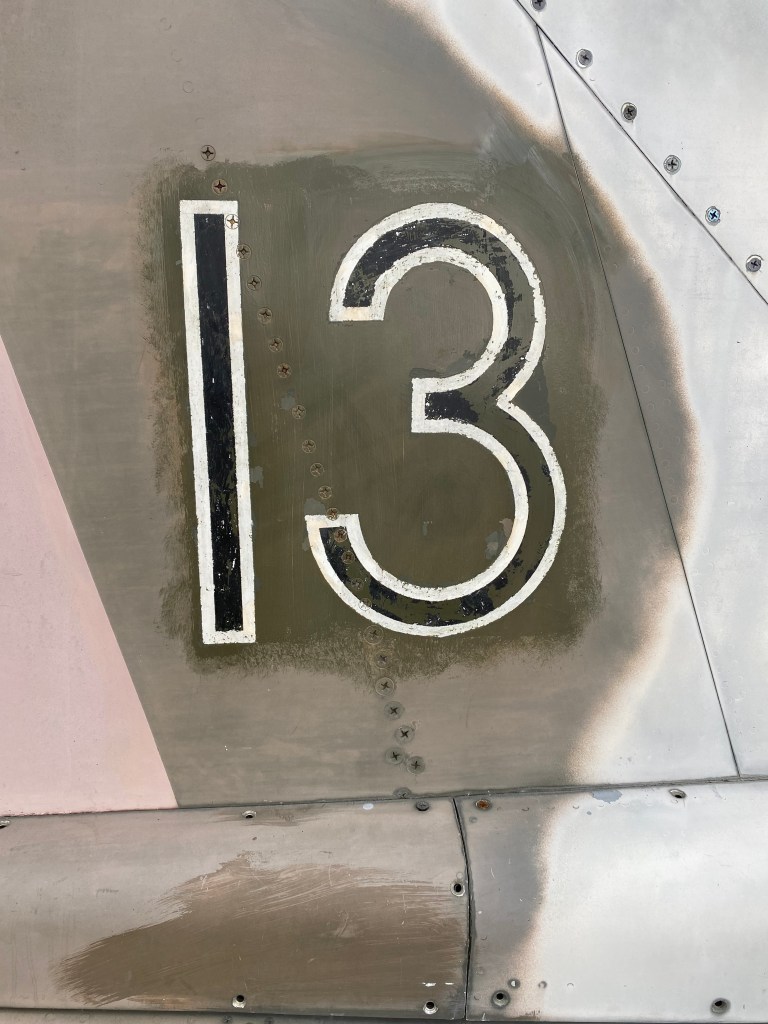

And the stbd tail number is also starting to reappear.

I’ve been able to source original spec bolts to replace the heavily corroded fasteners on the rear heatshields. Not cheap but they look infinitely better than the bolts coming out (some of which needed some heavy persuasion!)

Having accumulated all the parts required to rebuild the missing in-flight refuelling probe and arm installation it was time to refit the arm assembly. I still need to install the electric linear motor that opens the lower door but it’s 95% done now and looks the part. Eventually (!!) I’d really like to be able to extend this using the hydraulics – we’ll see if that’s a realistic aim at a later date!

And finally for this month, I have managed to locate a tail unit to be able to kit one of our 1000lb bombs. This Mk117 retarded tail has petals which open with a stowed parachute inside (photo of a deployed tail from the Newark Air Museum for reference).

As mentioned earlier we are still ‘All Systems Go’ for our Open House on Saturday August 7th. There is now a dedicated page here on the website (Open House 2021 tab in the main menus) and it would be greatly appreciated if you could take the time to register on the Eventbrite link. Although we should be clear of the current Covid restrictions by early August (I say that hopefully!!) registering will give us much better visibility on the numbers to anticipate welcoming and will help with the catering arrangements etc.

Thanks, as always, for the ongoing interest and support and I hope to be able to meet a few of you personally at Enstone on August the 7th.

Neil

MAY 2021 UPDATE: Well the promise of April soon gave way to a particularly wet May here in the UK with many of our visits to Enstone greeted with heavy skies and a lot of rain.

That said, I’ve still been able to make progress in a few areas not least of which was the sourcing of further previously missing parts and some additional spares for parts we already have on the shelf. With the aspiration still to return electrical power (at a minimum) to the aircraft and the serviceability of most of our parts being unknown it never hurts to have a few items in the back pocket just in case.

I’ve also found a new Electrical Bay cover which will hugely help keeping the Avionics bays dry(er).

There has been further progress in terms of restoring the completeness of the forward avionics bay with the sourcing of the last missing valve in the avionics cooling installation and the parts to complete the Rad Alt transceiver and Mode Selector switch junction box installation.

Meanwhile, on the bench, our ‘new’ Primary Heat Exchanger has been built up ready for it’s eventual installation back on the spine of the aircraft.

Looking slightly further ahead to the summer, I’m pleased to be able to announce that we have set a date for an ‘Open House’ day at Enstone for Saturday, August the 7th.

This will be an opportunity to come and visit the aircraft and hopefully see some of the progress we’ve made since our last open day in 2019.

Obviously this will be hugely dependant on the relevant Covid restrictions and protocols that may be in place at the time but hopefully we’ll be able to hold this as a relatively normal event.

I’ll keep the website and our various social media channels up to date as regards plans.

There is an ‘event’ set-up on our Facebook page to be able to register and interest and I’ll see if it’s possible to create something similar on here as we’ll need to have a reasonable idea of numbers as regards catering etc.

I had thought that at sometime during the course of the day we’ll remove a few of the external panels from the aircraft (if it’s of interest) for the keener modellers to be able to see a few of the internal parts and units. If there are any other requests or ideas that anyone would like for the day please don’t hesitate to get in touch and we’ll see what we can accommodate.

Obviously we’ll have most of our merchandise range also available as well as probably a few surplus Jaguar parts and collectables. Catering will be available on the day from the Flying Club.

And finally – don’t forget June the 20th is Fathers Day! There is still time to order Dad something Jaguar related so have a look at the merchandise page as there is something for every budget.

Thanks, as always, for the ongoing interest and support and I hope to be able to meet a few of you personally at Enstone on August the 7th.

Neil

APRIL 2021 UPDATE: Thankfully the gradual releasing of the COVID restrictions have meant we can really start to get back into the various joblists that have been on the back burner for most of the winter. April has seen progress on a number of fronts and it’s good to be back at Enstone on a regular basis (work commitments allowing) to move things forwards.

One of the first major tasks this month was to rebuild the cockpit air conditioning system that was completely missing when we bought the aircraft. Over time I have been rebuilding a kit of parts to refit the installation. It’s all now back in and the aft section of the nosewheel bay is pretty much complete. There’s a fair amount of wire locking to work around but I’ll hit that all in one go at a later date.

The refurbed Inflight Refuelling probe actuator has been refitted (more wire locking on the to-do list

We have also finally managed to track down an IFR pipe. It has a coupling adaptor and light pipe fitted but I have both in better condition in our parts stash so these will be swapped over before the pipe is fitted.

A major area of focus this month has been the noseleg. It was really starting to suffer from surface corrosion (I think it’s a cast magnesium alloy) so it has been thoroughly cleaned back to stabilise the condition and then filled and primed prior to repainting. It’s work in progress but is starting to look a lot better.

In the cockpit the aft bulkhead has been re-blacked where the original paint had badly faded. I’ve also sourced a cockpit altitude switch which has been cleaned up and fitted.

I’ve also had a play around and double-checked the fit of our ERU’s on one of the practice bombs.

And finally for this month we have been trialling some paint restoration. I’d thought that the paint was beyond help (in some areas it definitely is) but a complete repaint at the moment is a big financial step. In the meantime we can definitely give the exterior a freshen up and I have a few ideas on getting some life back into the grey next.

This month’s big merchandise news was the launch of our bespoke T-Shirt range, produced in association with our friends over at Flyingraphics (www.flyingraphics.com). Available both through the merchandise page here on the site (to UK buyers) and internationally through our eBay seller account (search for ‘jaguarXX764’) the shirts are available in four colours and a full range of sizes. Many thanks to everyone who has already purchased shirts (some of the benefits are already being seen in the tasks detailed above). As always with all our merchandise sales, the proceeds roll directly back to benefit the aircraft.

Finally, as usual, many thanks for sticking with us and the ongoing support and interest.

Neil

MARCH 2021 UPDATE: Finally some light appears as we approach (hopefully) the end of the lockdown tunnel. Here in the UK most of March has been spent in the tail end of our strict stay home lockdown but this has now started to ease and just before the end of the month we were allowed to start moving around with less restrictions.

So whilst the majority of the news this month still comes in the form of further sub-assembly tasks, we were able to get some jobs actually done on the aircraft at the tail end of March.:

The inflight refuelling installation had been previously been completely removed so sourcing replacements components has been high on the job list for a while. This hydraulic actuator, removed from another airframe, needed a cosmetic tidy up before it gets reinstalled in XX764. The next job will be to find a refuelling pipe!

The cockpit side consoles panels have all received a fresh coat of paint and missing Dzus fasteners replaced where required. When I’m happy that I’m done in terms of cleaning up the cockpit these will get refitted.

I’ve also finally got back on to the chopped spine harness. In order to get the aircraft electrically safe when we re-apply power I need to get all the cut harnesses terminated and the wiring that runs along the spine of the aircraft terminated to reattach the wings and tail electrically. It’s definitely time-consuming task as I need to record all the wire ID’s as I fit the connectors so that the cables on the aircraft side all match up. There are around 15 cut points like this to terminate on the loom with the same still needing to be done on the aircraft side.

Even whilst we were under lockdown the hunt for missing parts and spares continued. March’s new arrivals were these:

One rather exciting this month find was the (almost) final missing unit to complete the cockpit fit. The Fusing Unit had eluded me up until now so it’s been good to finally track one down. It was cleaned up on the bench prior to taking over to Enstone.

So finally as the month drew to a close the restrictions lifted to the extent that we were able to return to Enstone and start making some in-roads into the job list. The first task was to check that there hadn’t been any major water ingress into the cockpit over the winter. The canopy and windscreen had been double covered with covers and then a tarpaulin but it was still relief to find the cockpit dry. I then set about refitting a few of the parts that had been on the bench over the winter including the refurbed Engine Start Panel, the standby compass and the newly acquired Fusing Panel.

I still have a few things to do in the cockpit in terms of cleaning etc and would like to source a HUD camera but this is the cockpit as it now sits today:

And in terms of the nose avionics bays it’s nice to see some real progress filling the holes we inherited when we bought the aircraft:

The end of lockdown and the road map for the lifting of restrictions still gives us cause for optimism in terms of being able to hold some form of Open House at some point during the summer, if there is sufficient interest. When I can finalise a date it will be communicated through our social media channels as well as here on the website.

Thanks, as always, to everyone that continues to support us with ongoing purchases from our merchandise range which all directly assist with the sourcing of further parts. This month’s new additions have been directly assisted by sales of merchandise as well as some of the surplus parts that we continue to sell through out ebay seller profile ‘jaguarXX764’.

This month we have also added to our small range of face coverings available through the Red Bubble website. Have a look here for more information: https://www.redbubble.com/people/NeilAtterbury/shop?asc=u

And finally, as usual, many thanks for sticking with us and the ongoing support and interest.

Neil